Back to Product Page

|

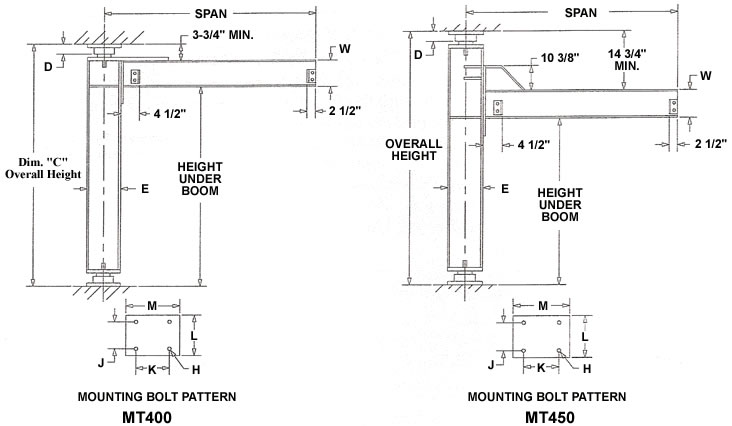

MAST

TYPE JIB CRANES

|

|

MT400

AND MT450 - 1/4 TON CAPACITY

|

|

|

|

|

|

CHART

1B - Boom Data |

|

|

| STANDARD

BOOM DATA |

Boom

Height (W) |

Beam Size |

Flange

Width (in) |

|

6" |

W6@12#/ft. |

4" |

|

8.125" |

W8@18#/ft. |

5-1/4" |

|

10.33" |

W10@26#/ft. |

5-3/4" |

|

12.5" |

W12@35#/ft. |

6-1/2" |

|

16.125" |

W16@45#/ft. |

7" |

|

18" |

W18@50#/ft. |

7-1/2" |

|

21" |

W21@62#/ft. |

8-1/4" |

|

24.125" |

W24@84#/ft. |

9" |

|

| Note:

For E and W dimensions, reference your crane's model number. |

|

|

PIVOT NO. |

D |

H |

J |

K |

L |

M |

|

15 |

2-3/4" |

13/16" |

7" |

9" |

10" |

12" |

|

20 |

3-1/4" |

13/16" |

7" |

10" |

10" |

13" |

|

25 |

3-3/4" |

13/16" |

9" |

12" |

12" |

15" |

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

1/4

Ton Capacity - PRICING - MT400 & *MT450

|

Dim.

"C" |

SPAN |

8' |

10' |

12' |

14' |

16' |

18' |

20' |

|

10' |

Model |

W8-W6-15 |

W8-W6-15 |

W8-W6-15 |

W8-W8-15 |

W8-W8-15 |

W10-W8-15 |

W10-W8-15 |

|

Weight |

430 |

465 |

525 |

600 |

635 |

865 |

920 |

|

Price |

$3,456

|

$3,522

|

$3,613

|

$3,778

|

$3,919

|

$4,610

|

$4,721

|

|

12' |

Model |

|

|

|

|

|

|

|

|

Weight |

475

|

500

|

560

|

630

|

670

|

910

|

960

|

|

Price |

$3,522

|

$3,581

|

$3,712

|

$3,895

|

$3,966

|

$4,689

|

$4,799

|

|

14' |

Model |

|

|

|

|

|

|

|

|

Weight |

510

|

535

|

590

|

665

|

790

|

960

|

1000

|

|

Price |

$3,576

|

$3,658

|

$3,818

|

$3,938

|

$4,439

|

$4,772

|

$4,886

|

|

16' |

Model |

|

|

|

|

|

|

|

|

Weight |

545

|

570

|

625

|

700

|

830

|

995

|

1045

|

|

Price |

$3,648

|

$3,710

|

$3,850

|

$4,011

|

$4,497

|

$4,837

|

$4,925

|

|

18' |

Model |

|

|

|

|

|

|

|

|

Weight |

575

|

600

|

660

|

740

|

870

|

1035

|

1085

|

|

Price |

$3,696

|

$3,782

|

$3,912

|

$4,058

|

$4,532

|

$4,886

|

$5,057

|

|

20' |

Model |

|

|

|

|

|

|

|

|

Weight |

610

|

635

|

695

|

880

|

915

|

1075

|

1340

|

|

Price |

$3,770

|

$3,829

|

$3,969

|

$4,574

|

$4,652

|

$5,013

|

$5,757

|

|

| *MT450

DROP CANTILEVER $783.00

LIST ADDER |

| Model

Explanation: use MT400 for a full cantilever jib or MT450

for the drop cantilever and then add the model number. |

| Example:

2 ton, 10' span, 20' overall height=MT400-W18-S12-15. The 18=E;

12=W; 15=pivot pin diameter. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Price of the item

you wish to purchase.

|

|

|

|

|

ACCESSORIES

|

|

Included

in the base price of all jib cranes: Jib End Stops, Installation

& Maintenance Manual (2), Touch-Up Paint

(1 spray can). |

|

Description |

Approx.

Ship Wt. |

Price |

Mast Type Manual Rotation Stops.One piece

welded to back of safety channel: two pieces

shippedloose for field welding. |

2 |

|

Tagline Assemblies.(if desired without collector).

Includes two trolley stops with tagline

angle,tagline cable, 2 cable clamps, 2 eye bolts, and

5 "S" hooks. Electrical wire is not included

(See "Flatand Round Cable") |

25 |

|

|

Flat and Round Wire- 4 conductor #14 |

.1/ft. |

|

|

Flat and Wire Cord Grip Connectors- for

4 conductor #14 flat wires |

3 |

|

|

Air Hose |

|

a. 3/8" ID |

.1/ft. |

|

|

b. 1/2" ID |

.1/ft. |

|

|

Wire Rope Trolley- (specify for flat or

round wire) |

1 |

|

|

MT450 - Drop Cantilever Connection |

|

|

Please contact our customer service dept. for pricing

on the following options: |

|

a. Special Paint |

|

b. Sandblasting |

|

c. Galvanizing |

|

d. C Track Festooning |

|

e. Any special requirement |

|

|

| STEP

2 - BOOM/MAST ASSEMBLY INSTALLATION |

| TIP:

Upper and lower pivot bearing assemblies are identical. |

|

|

|

|

|

|

|

| 2.1

Locate top pivot bearing assembly and bottom pivot bearing |

|

|

|

assembly

in the desired location (bolts by others). |

|

|

Make

sure the pivot bearing assemblies are in line and plumb |

|

|

through

pivot pin holes in the bearings (diagram 2A). |

|

|

|

|

|

|

|

| 2.2

If using optional rotation stops, execute step A of the rotation |

|

|

stops

section on Rotation Stops before proceeding to next step. |

|

|

|

|

|

|

|

| 2.3

Place the top and bottom pivot assemblies onto the top pivot

pin and |

|

|

bottom

pivot pin of the mast. Be sure the thrust washer is between

the

mast and bottom pivot bearing (diagram 2B). Take the

entire mast

assembly with pivot bearing assemblies and raise them into position.

Bolt the top pivot assembly to the overhead support and the

bottom

pivot assembly to the floor support. One-half inch (1/2”)

clearance

should be allowed between top fitting and overhead support to

ease

installation and for shimming if required. |

|

|

|

|

|

|

|

| 2.4

For a MT400: Bolt boom to mast using bolts for the top

of boom |

|

|

Diagram

2A. Plumbing the pivot bearing

assemblies. |

|

and

bolts for mast connection plate using hardware provided

(diagram 2C). |

|

|

|

|

|

For

a MT450: Bolt boom to mast using hardware provided (diagram

2D). |

|

|

|

|

|

|

|

| 2.5

Level boom to a point of 1/300 of span (in inches) above level.

Shim, if |

|

|

necessary,

between mast and back of boom plate (shims by others).

Make sure that shim has full contact at connection and that

there are

no voids. Torque nuts (chart 2A). |

|

|

|

|

|

|

|

| 2.6

Tighten mounting bolts (grade 5 or better) to manufacturer’s

specifications. |

|

|

|

|

|

|

|

|

|

Bolt Dia. |

Torque |

|

1/2" |

50 ft.-lbs. |

|

5/8" |

95 ft.-lbs. |

|

3/4" |

175 ft.-lbs. |

|

7/8" |

300 ft.-lbs. |

|

1" |

450 ft.-lbs. |

|

|

|

|

|

|

|

|

|

Diagram

2B. Installing pivot assembly on

pivot pin. |

|

|

|

Chart

2A. Torque Ratings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STEP

3 - ENDSTOP/TAGLINE INSTALLATION |

|

|

|

|

|

| 3.1

Endstop |

|

|

A)

Bolt endstops to end of boom closest to mast (diagram 3A).

B) Roll hoist trolley (by others) into place.

C) Bolt remaining endstops into place at the front of boom

(diagram 3A).

D) Torque nuts (refer to chart 2A, above, for proper torque

rating). |

|

|

|

|

| 3.2

Tagline Assembly |

|

|

A)

Bolt tagline bracket and an endstop to end of boom closest

to mast (diagram 3B).

B) Roll hoist trolley (by others) into place.

C) Bolt remaining tagline bracket and endstop into place at

the

front of the boom (diagram

3B). Torque nuts (refer to chart

2A, above, for proper torque

rating).

D) Bolt eyebolt to the tagline brackets. Be sure the eyes of

the

eyebolts are oriented toward each other. |

|

|

|

Diagram

3A. Endstop installation. |

|

|

|

|

|

|

|

E)

Run wire rope between eyebolts and clamp to form a loop

at each end. Tighten eyebolts so wire

rope is taught.

F) Add “S” hooks to wire rope and squeeze closed the

top

of the “S” hook.

G) Space “S” hooks evenly along wire rope and place

round

power cable/air hose through bottom

loop of the “S” hooks.

H) Squeeze bottom of “S” hook to grip wire, or tape

wire in

place. Do not squeeze too tightly or

damage may occur to

power cable or air hose. |

|

|

|

Diagram

3B. Tagline assembly installation. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| STEP

4 - OPTIONAL ACCESSORIES |

|

|

|

|

|

|

|

|

| 4.1

Rotation Stops |

|

|

|

|

A)

Prior to mast installation: Locate rotating stop block. Weld

stop block to under side of mast bottom

plate using E70xx

electrodes, per AWS D1.1 specifications

(diagram 4A). |

|

|

|

|

B)

Swing boom to the farthest position of use in one direction.

C) Place stationary stop block on lower pivot assembly against

the rotating stop block. |

|

|

|

|

|

|

|

|

|

|

|

|

|

D)

Weld stationary stop block to lower pivot assembly using

E70xx electrodes, per AWS D1.1 specifications

(diagram 4B).

E) Repeat Steps A-D for opposite direction.

F) Touch up with paint provided. |

|

|

|

|

| 4.2

Bottom Entry Collector |

|

|

|

A)

Connect wires through the pivot pin to the collector wires

(diagram 4C).

B) Place connector over the top of the pivot pin making sure

the

connected wires are pushed down inside

the pivot pin. |

|

|

|

C)

Lock the connector in place by tightening the set screws at

the

base of the collector.

D) Connect the collector to the stabilizer bolt mounted in the

mast

assembly.

E) Add appropriate size hole in the collector cover to allow

installation of hoist power cable to

collector.

F) Attach collector cover with mounting hardware provided. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Other

Options

• Flat Wire Conductor Cable

• Flat Wire Cord Grip Connectors

• Wire Rope Trolleys for Flat or Round Cable

• Fusible Disconnect Switch

• Powered Rotation |

|

|

|

|

|

Mast Type Jib

Cranes, Cranes, Articulating Jib Cranes, Gorbel Jib Cranes,

Jib Cranes, Floor Mounted Jib Cranes,

Gorbel Cranes, Hoist, and Jib Booms from your source for material

handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|