Back to Product Page

5100

SERIES FAN FORCED SUSPENDED

ELECTRIC UNIT HEATERS

|

|

3.3

KW THROUGH 50 KW SUSPENDED FAN FORCED UNIT HEATERS AVAILABLE

IN 1 OR 3 PHASE

FOR ALL STANDARD VOLTAGES FROM 208V TO 480V THAT CAN BE MOUNTED

TO PROVIDE

HORIZONTAL OR VERTICAL DISCHARGE.

|

|

|

|

|

|

Horizontal

or Vertical Discharge Airflow |

|

•

Heavy gauge welded steel cabinet with powder-coated finish and

control compartment

housing a master terminal board with a hinged and

latched access door, simplifying

wiring, installation and maintenance

• Copper clad steel sheath element with continuously brazed

steel fins formed to allow

side draw through airflow

• Units equipped with automatic resetting type limit control.

• Adjustable louvers for directional air flow control

• Units with model numbers ending in CA are factory wired

for low voltage controls

• Shipped fully assembled

• Made in U.S.A. |

|

Horizontal

Discharge

|

|

|

|

|

|

|

|

|

|

|

|

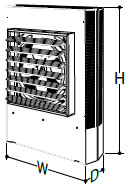

Taskmaster

Dimensions

|

|

|

|

|

KW

RATING

|

DIMENSIONS

(inches)

|

|

H

|

W

|

D

|

|

3.3

- 5.0

|

17

3/4

|

14

15/32

|

6

1/2

|

|

7.5

- 10.0

|

24

5/16

|

21

1/2

|

6

1/2

|

|

15.0

- 20.0

|

28

11/16

|

21

1/2

|

6

1/2

|

|

25.0

- 50.0

|

34

|

29

1/4

|

10

1/16

|

|

|

|

|

|

|

|

|

|

| FAN

and MOTOR: |

|

TEMPERATURE

CONTROLS: |

Totally

enclosed, 1-speed, 1-phase, permanently

lubricated, thermally protected motors with unit

bearings on 3 KW - 20 KW models. Totally

enclosed, 2-speed, 1-phase, permanently lubricated,

thermally protected motors with sleeve bearings

on 25 KW - 50 KW models. All motors mounted

with rubber insulators to minimize vibration & noise.

Fan override purges unit of residual heat at shutdown. |

|

Optional

low voltage and line voltage thermostats

available with an adjustable temperature range of

40°F to 110°F. Units with model numbers ending

in CA1 are factory wired for low voltage controls.

25 KW through 50 KW units are designed for two

stage heating operation. |

|

|

|

INSTALLATION: |

|

Unit

Heaters can be mounted for horizontal or vertical discharge. |

|

|

| LOUVER

ASSEMBLY: |

|

Louvers

are individually adjustable for directional control

of air flow up to 15° from straight horizontal. Optional

diffusers available for down flow (vertical discharge) applications. |

|

|

|

|

FIELD

INSTALLED OPTIONS: |

|

•

In-unit or wall mounted temperature control thermo-

stats low or line voltage.

• Summer fan switch to operate the fan only.

• Power disconnect switch.

• Heat stratification thermostat. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

PRICING

|

|

MODEL

NO.

|

KW

|

VOLTS

|

PHASE

|

AMPS

|

CONTROL

VOLTAGE

|

PRICE

EACH

|

|

HF2B5105N

|

5

|

240

|

1 / 3

|

20.8 / 18.1

|

240

|

|

|

3.7

|

208

|

12.1 / 10.4

|

208

|

|

|

HF2B5107CA1L

|

7.5

|

240

|

27.1 / 31.3

|

24

|

|

|

5.6

|

208

|

31.3 / 27.1

|

|

|

HF2B5110CA1L

|

10

|

240

|

41.2 / 24.0

|

|

|

7.5

|

208

|

36.1 / 20.8

|

|

|

P3P5105CA1N

|

5

|

480

|

3

|

6.1

|

|

|

P3P5107CA1N

|

7.5

|

9.1

|

|

|

P3P5110CA1N

|

10

|

12.1

|

|

|

|

|

|

HEATER

ACCESSORIES PRICING

|

|

|

MODEL

NO.

|

DESCRIPTION

|

MODEL

SIZE / TYPE

|

WT.

(LBS)

|

PRICE

EACH

|

|

A5105

|

Mounting

Brackets

|

3.3

KW to 5.0 KW

|

9

|

|

|

A5120

|

7.5

KW to 20.0 KW

|

13

|

|

|

T5100

|

Field

Installed

Thermostat

|

SPST

Line Voltage (Built-In) Stat

|

|

|

T5102

|

DPST

Line Voltage (Built-In) Stat

|

|

|

|

|

|

Installing

the Taskmaster Series

|

|

DETERMINING

HEATER REQUIREMENTS

Calculate the heating loads using the NEMA handbook or ASHRAE

guide. Then determine the quantity and size of

unit heaters to be used. To maintain uniform heat and reduce

stratified air, it is recommended that the total CFM of

the units turn the air over approximately 3 times per hour.

In instances where a large group of people are located

and normally in the same area, use a large number of lower KW

unit heaters. In warehouse areas or storage rooms

where heat distribution and constant temperatures are less important,

use fewer heaters of higher capacity. |

|

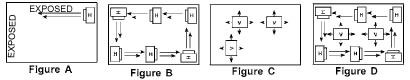

HORIZONTAL

MOUNT

Small rooms can be heated by one unit heater. Where two walls

are exposed, heaters should be mounted as shown

in Figure A. In larger rooms, units should he located so their

air streams wipe exposed walls without blowing at them.

Units should be located so that the air stream of one supports

that of another thus setting up a circulatory air

movement shown in Figure B. (Distance between units to be approximately

1-1/2 times published air throw.)

Units should not be mounted horizontally in areas having ceiling

heights in excess of 15-18 ft. |

|

VERTICAL

MOUNT

Units should be mounted vertically in high bay areas, or where

heater location would not interfere with plant operation

or traffic, Heaters should be situated to provide free air circulation.

Size and selection of units should be based on

recommended mounting height. Optional diffusers may best be

employed to reduce high air velocity and at the same

time disperse heated air in a uniform pattern. When unit heaters

are used to combat cold air inrush from opened

loading dock doors, one or more units should be arranged to

blow warm air across opening (Figure C). |

|

DUAL

MOUNTING

Where square footage is large and comfort essential, both horizontal

and vertical installations may best serve your

requirements as Figure D demonstrates. |

|

| Note:

Products in this section with factory installed controls are

subject to 100% cancellation/restocking charges. |

|

|

|

Fan Forced Suspended

Electric Unit Heaters, Electric Heaters, Suspended Heaters,

Radiant Forced Heater, Electric Heater, Space

Heaters, Horizontal or Vertical Discharge, Ceramic Heaters,

and Fan Heaters from your source for material handling equipment.

|

Back to Product

Page

|

| HOME

/

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|