Back to Product Page

|

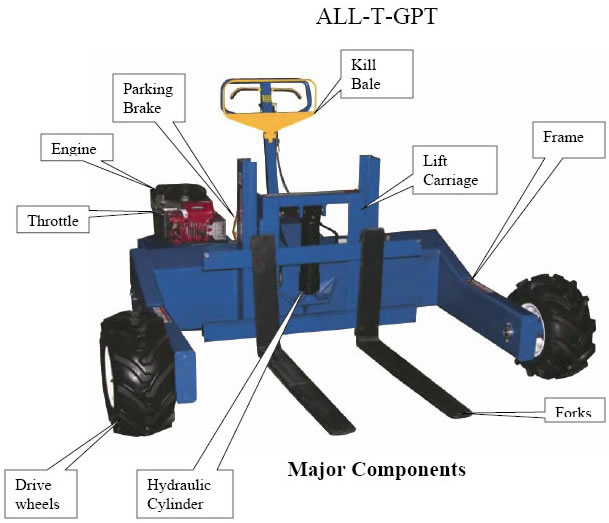

ALL

TERRAIN TRUCK WITH GAS POWERED TRACTION DRIVE

|

|

|

|

|

|

|

|

|

|

|

|

|

All-terrain

pallet truck with gas-powered traction drive system, great

for

moving heavy loads over rough terrain, features 2000 lbs.

or 4000 lbs.

capacity @ 18" load center, unit also includes powered

fork lift and

lower, steel construction for years of dependable use with

blue painted

finish.

|

|

|

| Standard

Features:

|

|

|

•

Briggs & Stratton 6HP gas-powered engine to power hydrostatic

traction

drive and fork lift |

|

|

|

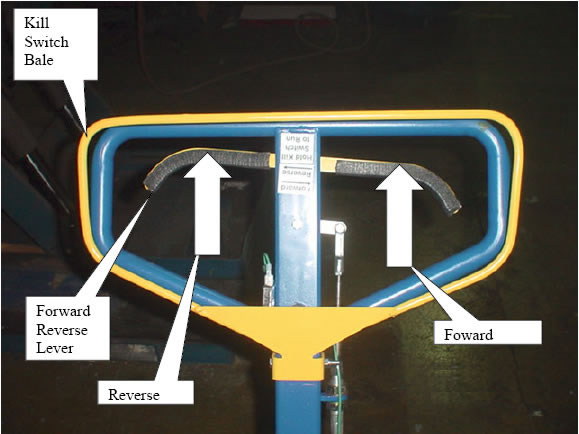

• Handle

with variable speed forward / reverse control and safety kill

switch

|

|

|

|

• Hydrostatic

transmission with hand-operated, Forward and Reverse control

|

|

|

|

|

|

|

| •

Powered fork raise and lower controlled with hand lever |

|

|

|

|

|

|

|

• Fork service

range is 2-5/8" lowered to 12" raised

|

|

|

|

|

|

|

|

• Forged

steel forks are 4" wide x 36" long and painted black

|

|

|

|

|

|

|

|

• Adjustable

fork width between 8" minimum and 36" maximum

|

|

|

|

|

|

|

|

• Usable

width between outriggers is 50"

|

|

|

|

|

|

|

|

• Overall

size of unit is 79" wide x 68" long (including handle)

|

|

|

|

|

|

|

|

• Pneumatic

steer wheels are 13" diameter x 4" wide each

|

|

|

|

|

|

|

|

• Drive wheels

are 18" diameter x 8-1/2" wide each

|

|

|

|

|

|

|

|

• Steering

arc is 150°

|

|

|

|

|

|

|

|

• Wheels

include sealed bearings for outdoor use

|

|

|

| •

3 m.p.h. walking speed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6HP

Briggs & Stratton

gas-powered engine

|

|

|

|

|

|

|

Drive

wheels are 18"

diameter x 8-1/2" wide

|

|

|

|

|

|

|

|

Emergency

Shut-Off

Release

|

|

|

|

|

Parking

Brake |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODEL |

CAPACITY |

FORK LENGTH (FL) |

LOAD CENTER (LC) |

|

ALL-T-2-GPT |

2000 lbs. |

36" |

18" |

|

ALL-T-2-GPT-L |

2000 lbs. |

48" |

24" |

|

ALL-T-4-GPT |

4000 lbs. |

36" |

18" |

|

ALL-T-4-GPT-L |

4000 lbs. |

48" |

24" |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

PRICES

|

|

Model

No.

|

Description

|

Overall

Length

|

Cap.

(lbs.)

@24" load

Center

|

Net

Wt.

(lbs.)

|

Price

|

|

|

All-Terrain

Pallet Truck Gas 2K 78"

|

78"

|

2,000

|

1500

|

$12,272

|

|

|

All-Terrain

Pallet Truck Gas 2K 90"

|

90"

|

2,000

|

1600

|

$13,245

|

|

|

All-Terrain

Pallet Truck Gas 4K 78"

|

78"

|

4,000

|

1625

|

$13,389

|

|

|

All-Terrain

Pallet Truck Gas 4K 90"

|

90"

|

4,000

|

1725

|

$14,380

|

|

Options

|

|

|

Gas

Powered All-Terrain Hopper

|

-

|

-

|

100

|

$13,600

|

|

|

|

Operations

|

|

|

|

Fill

engine with oil and gasoline per the engine instruction booklet.

Locate unit outdoors in an unobstructed area

to minimize the chance of collisions while becoming familiar

with operating the unit. Set choke and throttle per

engine instruction manual. Squeeze the kill switch bale with

left hand and pull the starter rope with right. After

engine starts, set choke to open and allow engine to warm up

for a few moments. Set the engine throttle to the

desired speed. Increasing the throttle will increase the speed.

Squeeze the left shift lever and the unit will start to

move forward. The further the lever is squeezed the faster the

unit will move. When the lever is released the unit

will stop. Squeeze the right lever and the unit will reverse.

If anything unexpected happens simply let go of the kill

switch bale, the engine and unit will stop. Practice driving

the unit around, getting used to how it turns. If you turn

sharp, the outer wheel will speed up and the inner wheel will

slow down. Get used to how the unit behaves

when turning sharp! Practice engaging from forward to reverse.

After a few minutes you should get the feel for

shifting the transaxle. When moving heavy loads, it may be necessary

to slow the unit down with the shift lever

resulting is less power demand. Do not shift from forward to

reverse rapidly! The change can cause the load

to shift on the forks and may damage transaxle. |

|

|

|

|

|

|

|

|

|

|

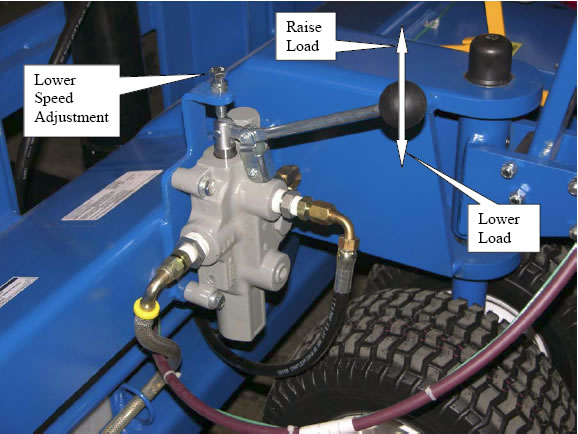

Raising

and lowering a load.

|

|

|

|

Raising

a load:

Release the shift lever. Speed the engine up to mid speed and

lift the valve lever gently with your hand. The load

should start to rise. Releasing the valve will cause the load

to stop and hold position. Lifting the raise lever again will

cause the load to continue to rise. At the top of the stroke,

you will hear the engine load. Release the raise lever.

Do not allow the hydraulics to over load at the end of the

stroke! Doing so for more then a few seconds will

cause the hydraulics to over heat and cause permanent damage.

Lowering a load:

Press the raise lever down gently with your hand. The engine

does not have to be running to lower the load. The load

will be lowered at a controlled speed. Releasing the lever will

cause the load to stop and hold position. The lowering

speed can be adjusted. If the load is lowered too fast the velocity

fuse in the cylinder will close, holding the load. If

this happens raise the load to reset the velocity fuse. Adjust

the adjustment screw to decrease lowering speed. |

|

|

|

|

|

|

|

|

|

|

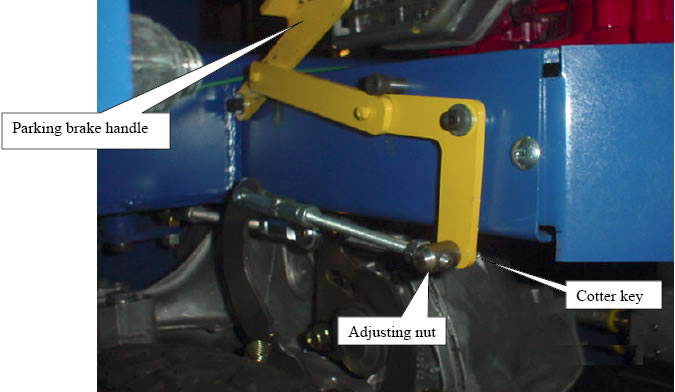

Parking

Brake

|

|

|

|

The

ALL-T-GPT is equipped with a locking parking brake. This

brake is not intended to be used as a dynamic

brake for slowing while engine is engaged or for steep grades.

To operate brake, simply pull the lever back

until it locks. Push the lever forward to release. Do not

use the parking brake for holding heavy loads on steep

grades. |

|

|

|

|

Transaxle

Release

|

|

|

|

If

the unit needs to be moved without the engine running, the transaxle

must be disengaged. Push the transaxle release

lever forward then down, to disengage the transaxle. |

|

|

|

|

|

|

|

|

|

|

Lifting

|

The

unit can be lifted by using the two holes located in the carriage

channels. Use proper clevises and chains (not

supplied with unit). |

|

|

|

|

|

|

|

|

|

|

Maintenance

|

|

|

|

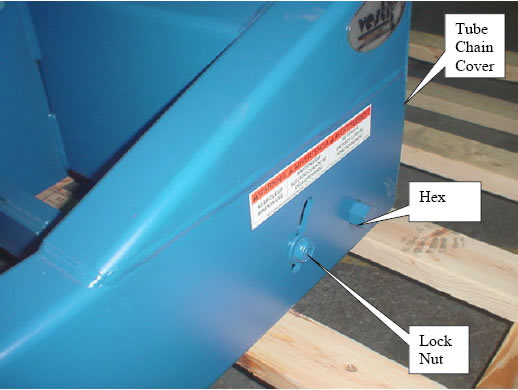

The

ALL-T-GPT should provide years of operation with little maintenance.

Follow the engine manufacture’s recom-

mendations on maintaining the engine. Every other engine oil

change, check the drive chain tension and lubricate the

drive chains with sticky spray grease. The chains should be

slightly loose (not tight) but not loose enough to allow the

chain to slap or jump. Inspect and lube the chains by removing

the tube chain covers. Adjust the chains by loosing the

lock nut and applying tension on the hex. |

|

|

|

|

|

|

|

|

|

There

are set screws on the front and rear sprockets, the drive shaft

coupling, motor pulley, and pump pulley.

Check to be sure set screws are tight. If loose retighten and

use red locktite to keep them from coming loose.

The rear sprocket should line up with the front sprocket on

that side. Check the belt for wear and replace if

necessary. With the belt tension removed, check the bearings

and shaft on the hydraulic pump drive for wear. Replace if necessary. |

|

|

|

To

adjust brake tension, remove cotter key. Adjust by turning rod

nut. Take care not to over tighten brake as it will

over heat damaging the transaxle |

|

|

|

|

|

|

|

|

|

| The

belt tension is spring loaded and requires no adjustment. Check

belt for wear or cracking, and replace as necessary. |

|

|

|

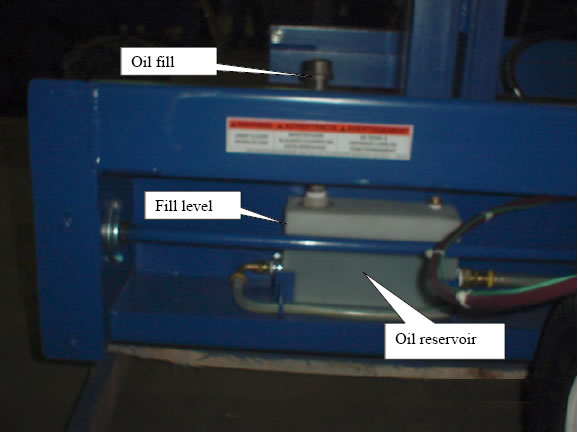

Check

hydraulic oil level and refill as necessary. Use an ISO 32 general

purpose hydraulic oil. Fill to 1” from top with

cylinder in down position. |

|

|

|

|

|

|

|

|

|

|

All Terrain Pallet

Truck with Gas Powered Traction Drive, Pallet Trucks, Pallet

Truck, Self Propelled Pallet Truck,

Pallet Lifter, Pallet Transporter, Moving Heavy Loads Over

Rough Terrain, and Outdoor Use from your source for

material handling equipment.

|

Back to Product Page

|