Back to Product Page

|

ALWAYS

OPEN...ALWAYS CLOSED

|

|

|

|

|

|

|

CLEAR-FLEX

II

|

|

|

|

|

|

|

the

new world standard for quality - featuring improved edges

for optimum safety and superior clarity assuring maximum efficiency.

|

|

|

|

|

|

CLEAR-FLEX

II -

|

|

|

Clearly

in your future!

|

|

|

|

|

| ENERGY

SAVINGS |

|

|

|

|

Our

Clear-Flex II® Strip Door saves you energy costs by

reducing the amount of heated or cooled air lost through your

unprotected opening. Superior design features, like rounded

edges to prevent cutting and concaveness to promote tight

sealing, assure maximum efficiency and safety. Our special

fabrication process keeps the strips hanging straight without

warping, even under temperature extremes. |

|

|

|

|

| DUST

CONTROL |

|

The

Clear-Flex II® Strip Door’s sealing properties prevent

the

movement of dust, dirt and other contaminants from one area

to another. This helps reduce overall clean-up costs in the

plant. |

|

|

|

|

|

|

|

| NOISE

CONTROL |

|

MINIMAL

MAINTENANCE |

|

|

|

|

|

Strip

doors and curtains provide a virtually unbreakable

sound barrier. Tests by an independent testing laboratory

have confirmed that Clear-Flex II® Strip Doors

significantly reduce the transmission of sound. Re-

searchers assigned our products a sound transmission

rating of Class 13. |

Maintenance

is minimal with the Clear-Flex II® Strip

Door. An occasional application of our exclusive Vinyl

Strip Cleaner is usually all that is required. Dilute as

required for cleaning tasks, but generally three (3) parts

water to one (1) part cleaner is sufficient. Apply by hand

(protective gloves recommended) with a soft cloth or

use in conventional steam cleaning equipment. (Material

Safety Data Sheets are supplied with orders.) |

|

|

|

|

| SPECIAL

SAFETY STRIPS |

|

|

|

|

|

Clear-Flex

II® Strip Doors are supplied with special

bright orange safety strips. These strips, when hung at the

extreme right and left of the Clear-Flex II® Strip Door,

clearly mark the throughways to help prevent accidents.

The safety strips are provided at no extra charge. (NOTE:

Safety Strips are not USDA approved; therefore,

unless specified, they are not supplied when USDA

material is ordered.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

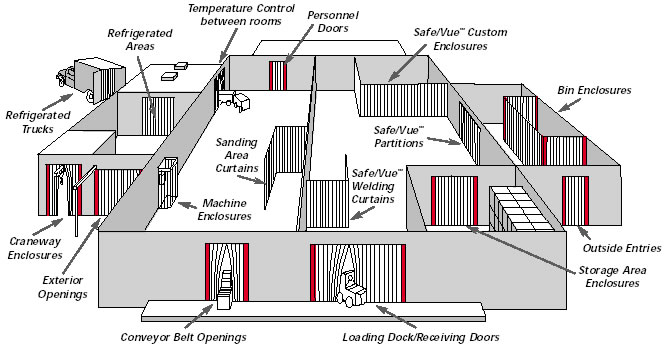

TAKE

A WALK THROUGH OUR ENVIRONMENTAL CONTROL APPLICATIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1.

Craneway enclosures |

|

7.

Sanding area curtains |

|

12.

Partitions |

| 2.

Exterior openings |

|

8.

Conveyor belt openings |

|

13.

Storage area enclosures |

| 3.

Refrigerated areas |

|

9.

Loading dock/receiving doors |

|

14.

Bin enclosures |

| 4.

Machine enclosures |

|

10.

Safe/Vue welding curtains |

|

15.

Outside entries |

| 5.

Temperature control between rooms |

|

11.

Nose-or dust-reducing machine

enclosures |

|

16.

Reefer doors and man other

applications |

| 6.

Personnel doors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| STANDARD

STRIP MATERIAL |

|

Formulated

for indoor/outdoor applications, withstanding temperatures

from -10°F to 150°F. Our most versatile material. Will

not discolor in

sun light. Is available in Smooth, Scratch-Guard® or Offset

Ribbed

in the following sizes: |

|

|

|

|

|

|

|

|

4"

x .060

(Smooth Only) |

|

24”

x .080

(Smooth Only)

24” x .120

(Smooth Only)

24” x .160

(Smooth Only) |

48"

x .060

(Smooth Only)

48" x .080

(Smooth Only)

48" x .120

(Smooth Only)

48" x .160

(Smooth Only) |

|

6"

x .060

(Smooth Only) |

|

|

8"

x .080

(Smooth Only) |

|

|

12"

x .080

(Smooth Only)

12" x.120

16"x.160 |

36”

x .080

(Smooth Only)

36” x .120

(Smooth Only)

36” x .160

(Smooth Only) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MaxBullet®

Mounting Systems

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

See

Bottom of page for

Installation Instructions

|

|

|

|

|

|

|

|

|

MaxBullet®

Aluminum

Our best seller! The aluminum

hardware won't rust or corrode. |

MaxBullet® HTP® Silver

Our exclusive cross-linked

polymer technology is more

cost effective and super tough. |

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Part No. of the item

you wish to purchase.

|

|

|

|

|

|

|

|

|

|

PRICING

FOR CLEAR-FLEX II® STRIP DOORS WITH VARIOUS

MOUNTING HARDWARE

|

|

|

Strip

Width and Thickness: 4" x .060

Strip Type: Standard/Smooth

Overlap (Inches/%): 1"/50% |

|

NOTE:

Part Numbers listed are for standard/smooth strip

materials only. |

|

|

|

Walk-In Aluminum |

|

Door Size W x H |

Part # |

Price |

| 2' x 3' |

|

$58 |

| 2' x 4' |

|

$75 |

| 2' x 5' |

|

$89 |

| 3' x 3' |

|

$81 |

| 3' x 4' |

|

$110 |

| 3' x 5' |

|

$133 |

| 4' x 3' |

|

$110 |

| 4' x 4' |

|

$147 |

| 4' x 5' |

|

$178 |

| 5' x 3' |

|

$133 |

| 5' x 4' |

|

$175 |

| 5' x 5' |

|

$224 |

|

|

|

|

|

|

|

|

Strip

Width and Thickness: 6" x .060

Strip Type: Standard/Smooth

Overlap (Inches/%): 2"/66% |

|

|

|

NOTE:

Part Numbers listed are for standard/smooth strip

materials only. |

Door Size

W x H |

MaxBullet®

Aluminum |

MaxBullet®

HTP

Silver |

Universal

Aluminum |

Universal

Galvanized |

|

Part # |

Price |

Part # |

Price |

Part # |

Price |

Part # |

Price |

|

3' x 4' |

|

$99 |

|

$73 |

|

$94 |

|

$80 |

|

3' x 5' |

|

$122 |

|

$92 |

|

$116 |

|

$99 |

|

3' x 6' |

|

$146 |

|

$110 |

|

$139 |

|

$119 |

|

3' x 7' |

|

$171 |

|

$127 |

|

$162 |

|

$139 |

|

4' x 4' |

|

$130 |

|

$97 |

|

$123 |

|

$105 |

|

4' x 5' |

|

$162 |

|

$121 |

|

$155 |

|

$132 |

|

4' x 6' |

|

$196 |

|

$146 |

|

$186 |

|

$158 |

|

4' x 7' |

|

$228 |

|

$169 |

|

$217 |

|

$183 |

|

5' x 4' |

|

$162 |

|

$121 |

|

$155 |

|

$132 |

|

5' x 5' |

|

$202 |

|

$151 |

|

$193 |

|

$164 |

|

5' x 6' |

|

$242 |

|

$182 |

|

$234 |

|

$196 |

|

5' x 7' |

|

$283 |

|

$212 |

|

$271 |

|

$230 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Part No. of the item

you wish to purchase.

|

|

|

|

|

|

|

|

|

Strip

Width and Thickness: 8" x .080

Strip Type: Standard/Smooth

Overlap (Inches/%): 2"/50% |

|

NOTE:

Part Numbers listed are for standard/smooth strip

materials only. |

|

|

Door Size

W x H |

MaxBullet®

Aluminum |

MaxBullet®

HTP

Silver |

Universal

Aluminum |

Universal

Galvanized |

|

Part # |

Price |

Part # |

Price |

Part # |

Price |

Part # |

Price |

|

3' x 7' |

|

$152 |

|

$112 |

|

$144 |

|

$123 |

|

4' x 7' |

|

$202 |

|

$150 |

|

$193 |

|

$162 |

|

5' x 7' |

|

$252 |

|

$187 |

|

$240 |

|

$204 |

|

6' x 7' |

|

$302 |

|

$225 |

|

$289 |

|

$243 |

|

7' x 7' |

|

$353 |

|

$228 |

|

$336 |

|

$286 |

|

8' x 7' |

|

$403 |

|

$261 |

|

$384 |

|

$325 |

|

3' x 8' |

|

$174 |

|

$128 |

|

$165 |

|

$140 |

|

4' x 8' |

|

$231 |

|

$172 |

|

$220 |

|

$186 |

|

5' x 8' |

|

$289 |

|

$227 |

|

$274 |

|

$232 |

|

6' x 8' |

|

$347 |

|

$257 |

|

$330 |

|

$281 |

|

7' x 8' |

|

$403 |

|

$299 |

|

$384 |

|

$325 |

|

8' x 8' |

|

$460 |

|

$342 |

|

$438 |

|

$372 |

|

3' x 9' |

|

$196 |

|

$126 |

|

$186 |

|

$158 |

|

4' x 9' |

|

$260 |

|

$168 |

|

$246 |

|

$209 |

|

5' x 9' |

|

$324 |

|

$241 |

|

$309 |

|

$261 |

|

6' x 9' |

|

$390 |

|

$289 |

|

$371 |

|

$314 |

|

7' x 9' |

|

$453 |

|

$337 |

|

$432 |

|

$365 |

|

8' x 9' |

|

$519 |

|

$385 |

|

$494 |

|

$417 |

|

| *Quick

Ship Item |

|

|

|

|

|

Strip

Width and Thickness: 12" x .120

Strip Type: Standard/Smooth

Overlap (Inches/%): 4"/66% |

|

NOTE:

Part Numbers listed are for standard/smooth strip

materials only. |

Door Size

W x H |

MaxBullet®

Aluminum |

MaxBullet®

HTP

Silver |

Universal

Aluminum |

Universal

Galvanized |

|

Part # |

Price |

Part # |

Price |

Part # |

Price |

Part # |

Price |

|

8' x 7' |

|

$554 |

|

$359 |

|

$529 |

|

$449 |

|

8' x 8' |

|

$633 |

|

$470 |

|

$603 |

|

$513 |

|

8' x 9' |

|

$713 |

|

$528 |

|

$679 |

|

$577 |

|

8' x 10' |

|

$792 |

|

$586 |

|

$754 |

|

$641 |

|

8' x 11' |

|

$870 |

|

$564 |

|

$829 |

|

$704 |

|

8' x 12' |

|

$950 |

|

$704 |

|

$905 |

|

$769 |

|

9' x 7' |

|

$624 |

|

$404 |

|

$595 |

|

$506 |

|

9' x 8' |

|

$713 |

|

$528 |

|

$679 |

|

$577 |

|

9' x 9' |

|

$803 |

|

$594 |

|

$765 |

|

$648 |

|

9' x 10' |

|

$892 |

|

$659 |

|

$849 |

|

$721 |

|

9' x 11' |

|

$980 |

|

$634 |

|

$934 |

|

$794 |

|

9' x 12' |

|

$1,070 |

|

$792 |

|

$1,018 |

|

$866 |

|

10' x 7' |

|

$692 |

|

$448 |

|

$659 |

|

$560 |

|

10' x 8' |

|

$792 |

|

$586 |

|

$754 |

|

$641 |

|

10' x 9' |

|

$892 |

|

$659 |

|

$849 |

|

$721 |

|

10' x 10' |

|

$989 |

|

$733 |

|

$942 |

|

$800 |

|

10' x 11' |

|

$1,089 |

|

$704 |

|

$1,036 |

|

$881 |

|

10' x 12' |

|

$1,188 |

|

$880 |

|

$1,131 |

|

$962 |

|

11' x 7' |

|

$763 |

|

$493 |

|

$726 |

|

$616 |

|

11' x 8' |

|

$870 |

|

$645 |

|

$829 |

|

$704 |

|

11' x 9' |

|

$980 |

|

$725 |

|

$934 |

|

$974 |

|

11' x 10' |

|

$1,089 |

|

$806 |

|

$1,036 |

|

$884 |

|

11' x 11' |

|

$1,196 |

|

$775 |

|

$1,140 |

|

$969 |

|

11' x 12' |

|

$1,306 |

|

$967 |

|

$1,244 |

|

$1,056 |

|

12' x 7' |

|

$831 |

|

$538 |

|

$792 |

|

$673 |

|

12' x 8' |

|

$950 |

|

$704 |

|

$905 |

|

$769 |

|

12' x 9' |

|

$1,070 |

|

$792 |

|

$1,018 |

|

$866 |

|

12' x 10' |

|

$1,188 |

|

$880 |

|

$1,131 |

|

$962 |

|

12' x 11' |

|

$1,306 |

|

$845 |

|

$1,244 |

|

$1,056 |

|

12' x 12' |

|

$1,425 |

|

$1,056 |

|

$1,357 |

|

$1,152 |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Part No. of the item

you wish to purchase.

|

|

|

|

|

|

|

|

|

Strip

Width and Thickness: 16" x .160

Strip Type: Standard/Smooth

Overlap (Inches/%): 6"/75% |

|

NOTE:

Part Numbers listed are for standard/smooth strip

materials only. |

Door Size

W x H |

Universal

Aluminum |

Universal

Galvanized |

|

Part # |

Price |

Part # |

Price |

|

10' x 10' |

|

$1,122

|

|

$1,027

|

|

10' x 11' |

|

$1,234

|

|

$1,052

|

|

10' x 12' |

|

$1,346

|

|

$1,232

|

|

12' x 10' |

|

$1,346

|

|

$1,232

|

|

12' x 12' |

|

$1,616

|

|

$1,479

|

|

12' x 13' |

|

$1,896

|

|

$1,605

|

|

12'x 14' |

|

$1,885

|

|

$1,725

|

|

14' x 12' |

|

$1,885

|

|

$1,725

|

|

14'x 14' |

|

$2,199

|

|

$2,013

|

|

14' x 15' |

|

$2,355

|

|

$2,157

|

|

14' x 16' |

|

$2,513

|

|

$2,301

|

|

15' x 12' |

|

$2,019

|

|

$2,006

|

|

15' x 14' |

|

$2,355

|

|

$2,150

|

|

15' x 15' |

|

$2,523

|

|

$1,682

|

|

16' x 11' |

|

$1,975

|

|

$1,682

|

|

16' x 12' |

|

$2,154

|

|

$1,833

|

|

16' x 14' |

|

$2,513

|

|

$2,140

|

|

16' x 15' |

|

$2,691

|

|

$2,293

|

|

16' x 16' |

|

$2,872

|

|

$2,629

|

|

|

| Clear-Flex

II® Strip Door Installation Instructions |

| Using

Universal Mounting Hardware |

|

|

|

|

|

|

|

|

|

TOOLS

NEEDED |

|

|

|

•

Pen or Pencil to Mark Drill Holes

• Drill

• 5/16” Diameter Fasteners

• Step Stool or Ladder

• Utility Knife to Cut Strips |

|

|

|

|

|

IMPORTANT |

|

Prior

to installation, unroll all door strips and place them

on a clean, flat surface in a warm atmosphere for a minimum

of twenty-four (24) hours. This will allow the strips to return

to their original form. |

|

|

|

|

|

1.

Mount the pre-drilled angle bracket in either the under |

|

|

header or wall position shown in Diagrams 1 and 2 using

appropriate fasteners supplied by others (recommended

5/16” diameter). |

|

|

|

|

|

2.

Place bolts in designated holes in angle, referring to Bolt |

|

|

Placement

Guide below. |

|

|

|

|

3.

Attach strips to bolts in angle, making sure that the |

|

|

concave

sides are facing each other (Diagram 3), starting

and ending with orange strips, securing with the 1 foot

sections of pre-drilled face plates. |

|

|

|

|

4.

Once all of the door strips have been attached, the strips |

|

|

can

be trimmed to leave ¼” of clearance from the floor

surface. Your PVC door strips may be trimmed by using

a common utility knife to score and then be torn by hand.

The door strips need to hang for 24 to 48 hours

before final trim to allow for proper alignment |

|

|

|

|

|

|

|

|

|

MODIFICATION

OF UNITS

|

|

|

|

|

1.

Measure width and determine size of opening if smaller |

|

|

than

standard unit. |

|

|

|

|

2.

Lay out pre-drilled mounting angles, measure exact length |

|

|

|

|

|

required,

cut excess out of the shortest length. |

|

|

|

|

|

|

3.

Follow installation instructions for mounting position |

|

|

|

desired

shown in Diagrams 1 and 2 |

|

|

|

|

|

|

4.

If you are not able to complete the recommended overlap |

|

|

|

of

the last strip, you have the option of altering the overlap

on the last few strips or trimming the excess to match the

opening using a utility knife and a straight edge to score the

material then tearing off by hand. |

|

|

|

BOLT

PLACEMENT GUIDE

*Arrows represent recommended placement of bolts.

|

|

|

|

PARTIAL

OVERLAP

|

FULL

OVERLAP

|

|

|

| 6"

WIDE MATERIAL |

|

|

|

|

| 8"

WIDE MATERIAL |

|

|

|

| 12"

WIDE MATERIAL |

|

|

|

| 16"

WIDE MATERIAL |

|

|

|

| Clear-Flex

II® Strip Door Installation Instructions |

| Using

the Maximus System™ Hardware |

|

|

|

|

|

|

|

|

|

|

|

TOOLS

NEEDED |

|

|

|

•

Pen or Pencil to Mark Drill Holes

• Drill

• 5/16” Diameter Fasteners

• Step Stool or Ladder

• Utility Knife to Cut Strips |

|

|

|

|

|

IMPORTANT |

|

Prior

to installation, unroll all door strips and place

them on a clean, flat surface in a warm atmosphere

for a minimum of twenty-four (24) hours. This will

allow the strips to return to their original form. |

|

|

|

|

|

1.

Mount the MaxBullet™ hardware bracket in either |

|

|

the under header or wall position shown in Diagrams

1 and 2 using appropriate fasteners supplied by others

(recommended 5/16” diameter). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Press the door strips onto the “bullets” of the hardware |

|

|

|

|

bracket

making certain that the concave sides are facing

each other (Diagram 4). Attach strip numbers 1 and 3

(see Diagram 3) with concave side toward you, leaving

desired spacing between strips as indicated by the

diagram on reverse side of this sheet. |

|

|

|

|

|

|

|

|

Diagram

4 |

|

|

|

|

|

|

|

|

|

|

3.

Attach strip number 2 with concave side away from you |

|

|

|

|

over

strip numbers 1 and 3 (Diagram 3). |

|

|

|

|

4.

Attach all of the remaining door strips in the same manner |

|

|

as

in Steps 2 and 3 making certain that the concave sides face

each other (Diagram 4). |

|

|

|

|

5.

Once all of the door strips have been attached, the strips |

|

|

can

be trimmed to leave ¼” of clearance from the floor

surface. Your PVC door strips may be trimmed by using a

common utility knife to score and then be torn by hand. The

door strips need to hang for 24 to 48 hours before final

trim to allow for proper alignment. |

|

|

|

|

*

NSF certification applies when hardware is installed with approved

low-temp PVC strip material. |

|

|

|

|

|

STRIP

PLACEMENT GUIDE

|

|

|

|

PARTIAL

OVERLAP

|

FULL

OVERLAP

|

|

|

| 6"

WIDE MATERIAL |

|

|

|

|

| 8"

WIDE MATERIAL |

|

|

|

| 12"

WIDE MATERIAL |

|

|

|

| 16"

WIDE MATERIAL |

|

|

|

| Clear-Flex

II® Strip Door Installation Instructions (Food Service Model) |

| Using

the Maximus System™ Hardware |

|

|

|

|

|

|

|

|

|

|

TOOLS

NEEDED |

|

|

|

•

Pen or Pencil to Mark Drill Holes

• Drill

• 5/16” Diameter Fasteners

• Step Stool or Ladder

• Utility Knife to Cut Strips |

|

|

|

|

|

IMPORTANT |

|

Prior

to installation, unroll all door strips and place them

on a clean, flat surface in a warm atmosphere for a

minimum of twenty-four (24) hours. This will allow the

strips to return to their original form. |

|

|

|

|

|

1.

Mount the MaxBullet™ hardware bracket |

|

|

using lag screws provided on the inside wall of walk-in,

centered appropriately above conventional door

opening. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.

Seal opening at ends of MaxBullet™ hardware |

|

|

|

bracket with NSF-approved silicone sealant

(Diagram 1). |

|

|

|

|

|

|

|

3.

Press the door strips onto the “bullets” of the |

|

|

|

hardware

bracket making certain that the concave

sides are facing each other (Diagram 3). Attach strip

numbers 1 and 3 (see Diagram 2) with concave side

toward you, leaving desired spacing between strips as

indicated by the diagram on reverse side of this sheet.

Then attach strip number 2 with concave side away

from you. Proceed with strip number 5 toward you,

again leaving the appropriate spacing as per diagram

on reverse side of this sheet. Proceed until all strips

are in place. |

|

|

|

|

|

|

|

4.

Once all of the door strips have been attached, the |

|

|

|

strips

can be trimmed to leave ¼” of clearance from

the floor surface. Your PVC door strips may be

trimmed by using a common utility knife to score and

then be torn by hand. The door strips need to hang

for 24 to 48 hours before final trim to allow for

proper alignment. |

|

|

|

|

|

|

|

STRIP

PLACEMENT GUIDE

|

|

|

|

PARTIAL

OVERLAP

|

FULL

OVERLAP

|

|

|

| 6"

WIDE MATERIAL |

|

|

|

|

| 8"

WIDE MATERIAL |

|

|

|

| 12"

WIDE MATERIAL |

|

|

|

| 16"

WIDE MATERIAL |

|

|

|

Clear-Flex, Aleco

Strip Doors, Plastic Strip Door, PVC Strip Door, Strip Door,

Strip Doors, Vinyl Strip Door, Welding Strip, Truck

Mount Strip Door, Insect Barrier, and Traffic Doors from your

source for material handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|