Back to Product Page

CONCRETE

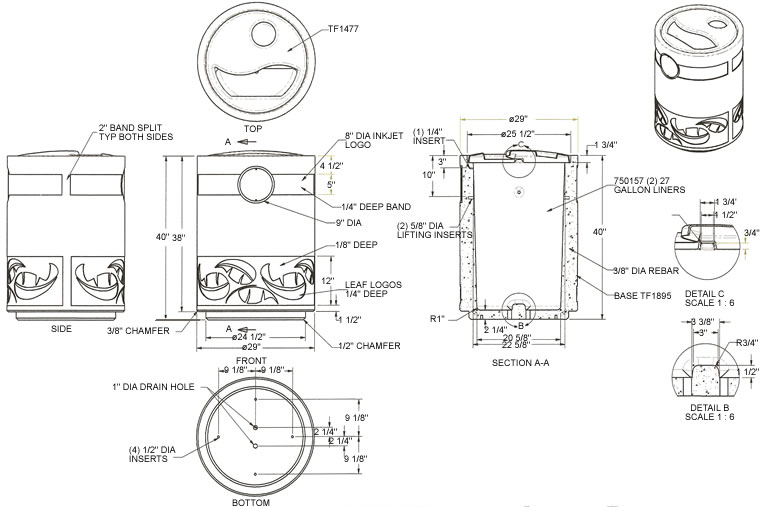

RECYCLING CENTER - WS1196

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

Concrete

recycling center includes two logos and two 27

gallon liners. |

|

|

|

|

|

|

|

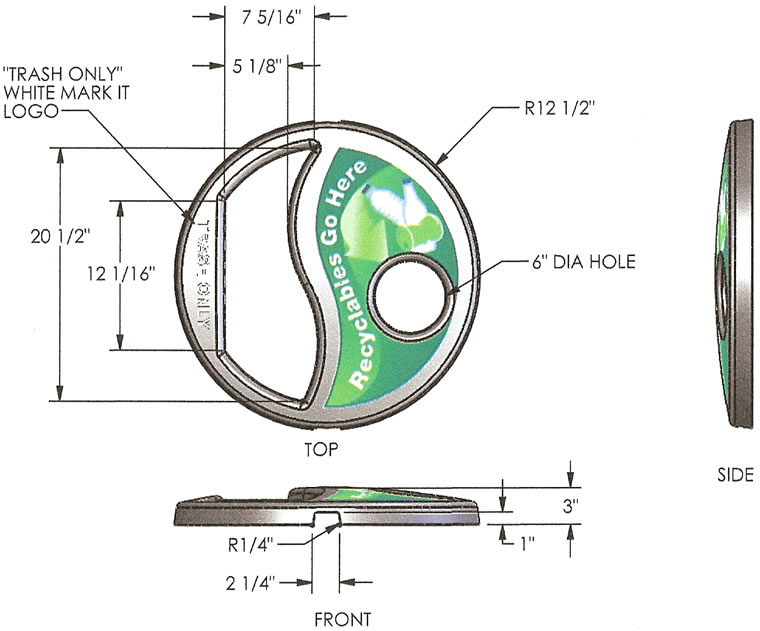

Size:

29" Dia. x 42"H

Unit Weight: 960 lbs.

Unit Capacity: 2 - 27 gallon units

Reinforcing: 1/4” & 3/8" Dia. steel rebar

Material: Reinforced concrete, Plastic

Logo Options: 8" Dia. inkjet recycle arrow logo

included.

Custom cast band.

Parts: 1 Plastic 2-hole lid

1

Concrete base

1

Security cable assembly

2

Polyethylene liners

1 Security Cable

4

Elevator bolts

Logo Options: 2 Recycle arrows 8" dia

1 Recyclables Go Here

1

Trash

1

Only |

|

Anchoring:

|

|

|

|

Includes

(4) 1/2" threaded inserts on bottom for optional anchoring. |

|

|

|

Model:

WS1196

Price: $1,289.20 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Available Colors

|

|

|

|

PLASTIC

COLORS FOR TOPS ONLY

|

|

|

|

|

|

|

|

|

|

Concrete

Specification

|

|

|

1.1

SUMMARY

A. Section includes: Furnish

Precast Concrete indicated on drawing or specified herein.

1.2 REFERENCES

A. American Society for

Testing & Material

1.

ASTM C33 2. ASTM C150 3.ASTM C31

1.5 SUBMITTALS

A. Submit Product data,shop

drawings and samples.

1.

Product Data: Manufacturer’s specifications and technical

data edited specifically for proposed system,

including

the following specific Information:

a:

Detailed specification of construction fabrication.

b:

Manufacture’s installation instructions

c:

Maintenance literature

d:

Product warranty

2.

Shop Drawings: Indicate pertinent dimensions, general construction,

component connections anchoring

methods,

hardware and installation procedures.

3.

Samples as requested by Architect.

1.6 QUALITY ASSURANCE

A. Qualifications of Manufacture:

Manufacturer to be prequalified by specifier prior to bidding.

Failure to comply

will result in disqualification of bid. Manufacturer to have

at least five years experience in the manufacture of

precast concrete field proven for at least five years.

1.10 WARRANTY

Manufacturer

shall submit a written warranty for precast products for the

period of two years upon acceptance.

2.1 MANUFACTURERS

A. Clarification Note:

Drawings and installation specification are based on manufactures

proprietary literature

from

us. Other manufacturers shall comply with minimum levels of

material and detailing indicated on

drawings

of specified herein.

B. All Precast products

for this project shall be of one manufacturer.

2.2 MATERIALS

A. Portland cement: ASTM

C150 specifications for Portland cement.

B. Aggregates: All aggregates

to meet ASTM C33 specifications, to be cleaned of foreign

matter and properly

graded

to size.

C. Coloring: Pigments

used shall be inorganic,resistant to alkalinity and used as

per manufacturers

recommendations.

|

|

|

HYPEL™

LLDPE 3170 UV 8 NATURAL ** LINEAR LOW DENSITY POLYETHYLENE,

7.0 MFI

|

|

|

TYPICAL

PROPERTY VALUES†

|

|

|

PROPERTY

|

METHOD

|

UNIT

|

VALUE

|

| PHYSICAL |

| Specific

Gravity |

ASTM

D792

|

|

0.935

|

| Metal

flow (190°C / 2.16 kg) |

ASTM

D1238

|

g/10

min

|

7

|

| MECHANICAL

@ 73°F |

| Tensile

Strength at Yield |

ASTM

D638

|

psi

|

2720

|

|

MPa

|

18.8

|

| Flexural

Modulus - 1% Secant |

ASTM

D790

|

psi

|

100,000

|

|

MPa

|

655

|

| ARM

Impact 1/8" (Notched) @-40°C |

ASTM

D562B

|

ft-lb/in

|

79

|

| Hardness

(Shore D) |

ASTM

D785

|

-

|

-

|

| THERMAL |

| 264

psi - ASTM, 1.80 MPa-ISO |

ASTM

D648

|

°C

|

35

|

|

°F

|

95

|

| 66

psi - ASTM, 0.45 MPa-ISO |

ASTM

D648

|

°C

|

52

|

|

°F

|

125

|

| OTHER |

| ESCR

(100% IGEPAL) |

|

|

>1000

|

|

|

**When

used unmodified for food contact applications, this copolymer

will comply with the U.S. Food and Drug

Administration Food Additive Regulation 21 CFR 177.1520(c)3.1a.

This section does not include use in packing or

holding food during cooking. This product is limited to use

in contact with food only under the conditions of use C

through H described in table 2 of Sec. 176.170(c), and when

contacting fatty foods of Types III, IVA, V, VII-A,

and IX described in table 1 of Sec. 176.170(c), the finished

articles are to have a volume of at least 18.9 liters (5

gallons). The uses cited are subject to good manufacturing practices

and any limitations, which are part of the regu-

lations. The regulations should be consulted for complete details.

†The data listed here fall within the normal range of product

properties, but they should not be used to establish speci-

fication limits or used alone as a basis for design. This information

is not intended as a warranty of any kind. Buyers

must make their own representative test and assume all risks

of use, whether used alone or in combination with other

products. Entec Polymers, LLC assumes no obligation or liability

of any advice furnished by it or results obtained with

respect to these products. All warranties expressed or implied

including warranties of merchantability for a particular

purpose or use are excluded and disclaimed. Entec Polymers,

LLC assumes no liability for use of products in infringe-

ment of any patent. The foregoing limitation of remedy and exclusion

of liability is reflected in and is part of the

consideration for the price, at which the products are sold

by Entec Polymers, LLC. All data displayed herein has been

obtained via testing of injected molded specimens of natural

color. Pigmentation may affect certain properties to various

degrees. |

|

Concrete Recycling

Centers, Concrete Trash Receptacles, Concrete Recycling Waste

Receptacles, Trash Receptacles, Metal

Trash Receptacles, Steel Trash Receptacles, Weathergard, Polysteel,

Streetscape, Aspen Series, and American Series from

your source for material handling equipment.

|

Back to Product Page

|