Back to Product Page

|

SERIES

JG PORTABLE MIXERS

|

GEAR

DRIVE MIXER, CLAMP OR CUP PLATE MOUNT

HEAVY HELICAL GEAR, 350 RPM, GREASE LUBE

|

|

|

|

|

The

most powerful mixers for the most difficult

mixing applications. Grease filled gearbox

eliminates oil seal and the possibility of oil

contamination of process. |

|

|

|

Features |

|

•

No clutches to slip, wear or replace.

• 316SS propellers and shafts are standard.

Optional coatings such as rubber, PVC or

Teflon® also available.

• Square pitch 1.0 ratio marine propellers are

used exclusively. Flow coefficients and power

consumption characteristics equal those of the

best hydrofoil impeller designs.

• Vibration-absorbing pad standard.

• Motors are available in TEFC or explosion-

proof enclosures (1750 rpm, 56C frame). Air

motors also available.

• Gears run in grease lubrication. Cannot leak oil.

• All JG mixer shaft bearings are permanently

lubricated.

• Variable speed drives also available.

• Cast aluminum housing.

• Mounting clamp has adjustable angle of entry by

indexed ball-and-socket design to achieve

various process results.

• Fixed cup plate mount optional on 1/3 HP

through 1-1/2 HP. Standard on 2 HP and larger

models. |

|

Model

JG-3.0

|

Model

JG-3.4

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

PRICES

|

|

Model

No.

|

Motor

Description

|

A

|

B

|

C

|

D

|

Wt.

(lbs)

|

Prices

|

|

Shaft

Length

|

Single

|

Dual

|

Shaft

Dia.

|

Single

Prop

|

Dual

Prop

|

|

Totally-Enclosed

Fan-Cooled (TEFC)

|

|

JG-2.0

|

1/3

HP-1-115/230*

|

48"

|

17

5/8"

|

10"

|

8"

|

3/4"

|

65

|

|

|

|

JG-2.1

|

1/3

HP-3-230/460*

|

48"

|

17

3/8"

|

10"

|

8"

|

3/4"

|

65

|

|

|

|

JG-3.0

|

1/2

HP-1-115/230*

|

48"

|

18

1/2"

|

12"

|

10"

|

3/4"

|

70

|

|

|

|

JG-3.1

|

1/2

HP-3-230/460*

|

48"

|

17

5/8"

|

12"

|

10"

|

3/4"

|

70

|

|

|

|

JG-4.0

|

3/4

HP-1-115/230*

|

60"

|

18

3/4"

|

13"

|

11"

|

3/4"

|

80

|

|

|

|

JG-4.1

|

3/4

HP-3-230/460*

|

60"

|

18

1/8"

|

13"

|

11"

|

3/4"

|

80

|

|

|

|

JG-5.1

|

1

HP-3-230/460*

|

60"

|

18

3/8"

|

14"

|

12"

|

1"

|

90

|

|

|

|

JG-6.1

|

1

1/2 HP-3-230/460*

|

60"

|

18

3/4"

|

15"

|

13"

|

1"

|

90

|

|

|

|

JG-7.1†

|

2

HP-3-230/460*

|

60"

|

20

5/8"

|

16"

|

14"

|

1

1/4"

|

95

|

|

|

|

JG-8.1†

|

3

HP-3-230/460

|

72"

|

21

5/8"

|

16"

|

15"

|

1

1/4"

|

115

|

|

|

|

Explosion-Proof

Class 1 Group D (EP)

|

|

JG-2.2

|

1/3

HP-1-115/230

|

48"

|

20

1/2"

|

10"

|

8"

|

3/4"

|

75

|

|

|

|

JG-2.3

|

1/3

HP-3-230/460

|

48"

|

17

3/8"

|

10"

|

8"

|

3/4"

|

75

|

|

|

|

JG-3.2

|

1/2

HP-1-115/230

|

48"

|

21"

|

12"

|

10"

|

3/4"

|

90

|

|

|

|

JG-3.3

|

1/2

HP-3-230/460

|

48"

|

19

5/8"

|

12"

|

10"

|

3/4"

|

90

|

|

|

|

JG-4.2

|

3/4

HP-1-115/230

|

60"

|

21

1/2"

|

13"

|

11"

|

3/4"

|

90

|

|

|

|

JG-4.3

|

3/4

HP-3-230/460

|

60"

|

19

5/8"

|

13"

|

11"

|

3/4"

|

90

|

|

|

|

JG-5.3

|

1

HP-3-230/460

|

60"

|

20

1/2"

|

14"

|

12"

|

1"

|

100

|

|

|

|

JG-6.3

|

1

1/2 HP-3-230/460

|

60"

|

20

1/2"

|

15"

|

13"

|

1"

|

100

|

|

|

|

JG-7.3†

|

2

HP-3-230/460

|

60"

|

22

1/8"

|

16"

|

14"

|

1

1/4"

|

105

|

|

|

|

§

Air Motor

|

|

JG-3.4§

|

1/3

HP to 1/2 HP AIR

Air Requirements: 12-20CFM

at 40-80PSI

|

48"

|

17

1/8"

|

12"

|

10"

|

3/4"

|

65

|

|

|

|

JG-4.4§

|

3/4

HP AIR

Air Requirements: 30CFM at 60PSI

|

60"

|

18"

|

13"

|

11"

|

3/4"

|

70

|

|

|

|

JG-5.4§

|

1

HP AIR

Air Requirements: 40CFM at 40PSI

|

60"

|

19

1/8"

|

14"

|

12"

|

1"

|

70

|

|

|

|

JG-6.4

|

1

1/2 HP AIR

Air Requirements: 55CFM at 60PSI

|

60"

|

19

1/8"

|

15"

|

13"

|

1"

|

75

|

|

|

|

JG-7.4†

|

2

HP AIR

Air Requirements: 65CFM at 70PSI

|

60"

|

15

5/8"

|

16"

|

14"

|

1

1/4"

|

80

|

|

|

|

JG-8.4†

|

4

HP AIR

Air Requirements: 125CFM at 90PSI

|

72"

|

16

3/4"

|

16"

|

15"

|

1

1/4"

|

80

|

|

|

|

*

Mill and Chemical Duty Motor available (Prices on request).

§ Requires Air Set

† Cup Plate Mount Only. |

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

*

Mill and Chemical Duty Motor available (Prices on request).

§ Requires Air Set

† Cup Plate Mount Only. |

|

|

|

|

|

|

|

|

ACCESSORIES

AND OPTIONS

|

|

|

|

|

|

|

| STABILIZER

RINGS: Price addition for stabilizer rings. |

|

NON

STANDARD SHAFT LENGTHS - No

charge to furnish custom shafts shorter than the

standard length. Longer shafts are priced as follows: |

|

|

|

|

|

Prop

Dia.

|

Price

Addition (316SS)

|

|

Up

to 6"

|

|

|

Up

to 9"

|

|

|

Up

to 14

|

|

|

Up

to 17"

|

|

|

|

|

|

|

|

|

|

|

|

Shaft

Dia.

|

Maximum

Length

|

Any

Length From Standard to 72"

|

Any

Length From 72" to Maximum

|

|

5/8"

|

48"

|

N/A

|

N/A

|

|

3/4"

|

60"

|

|

N/A

|

|

1"

|

72"

|

|

N/A

|

|

1

1/4"

|

84"

|

|

|

|

|

|

|

|

AIR

SETS, including regulator, filter and lubricator are

available for air powered mixers as follows: |

|

|

|

|

|

|

Air

Set For 1/4 through 3/4 HP Air Motors

P/N 100803 $718.80 |

|

|

|

|

|

|

|

|

Air

Set For 1 HP and Larger Air Motors

P/N 100804 $940.80 |

|

|

|

|

Mixer

Selection

|

|

|

|

|

|

|

|

These

mixers have been designed, engineered

and built to provide long life and trouble-free

service in a wide variety of blending/mixing

operations. These mixers are popularly used to: |

final product, and other parameters. Our

portables are available at either 350 or 420

RPM (gear-driven) or 1750 RPM (direct-

drive). If you have any questions or wish

to discuss your mixing/blending application

with us, please feel free to call one of our

sales engineers. |

|

|

|

|

1.

Blend liquids.

2. Suspend or dissolve solids

3. Disperse immiscible liquids

4. Disperse small amounts of gases in

liquids |

|

|

|

|

|

|

|

Selection

Chart |

|

|

|

|

|

|

|

|

|

|

|

The chart below is intended to provide some

basic guidelines for selecting the proper

mixer(s) to provide mild blending of various

viscosity liquids in different size tanks. This

chart is based on an approximate mix/blend

time for two liquids of 30 minutes, with both

liquids already in the tank. Mixing times will

be shortened if one liquid is added to a

second liquid while the mixer is operating.

Powders should always be added while the

mixer is running. This chart also applies to the

suspension of solids with settling velocities of

less than one foot per minute. For more rapid

or vigorous mixing, use a mixer one or two

sizes larger. Dual propellers are recommended

for tanks 1000 gallons and larger at viscosity's

of 1000 CPS and higher. |

|

These

portable mixers can be clamp- or base-

mounted on beams, tank walls or other

supports. Angle of entry may be adjusted to

meet specific mixing requirements. These

portable mixers find use in a variety of dif-

ferent industrial applications…waste treat-

ment, water treatment and batch chemical

preparation. These portables are also ideal

for mixing paints, varnishes, polymers, textile

sizes and dyes, pharmaceuticals, soaps and

countless other materials from 1 to over

25,000 CPS viscosity. In the following pages,

we present specifications, dimensions and

dimensional drawings and other information

to help you select the proper mixer for your

application, depending on the size of the

batch, the size of the batch, components and |

|

|

|

|

|

|

|

|

|

|

|

Viscosity

CPS

|

Up

to 50 Gallons

|

Up

to 100 Gallons

|

Up

to 200 Gallons

|

Up

to 500 Gallons

|

Up

to 1000 Gallons

|

Up

to 2000 Gallons

|

Up

to 3000 Gallons

|

Up

to 5000 Gallons

|

|

<1

|

BN-3.0

|

BN-3.0

|

JD-2.0

|

JD-2.0

|

JG-2.0

|

JG-2.0

|

JG-2.0

|

JG-4.0

|

|

<100

|

BN-3.0

|

BN-3.0

|

JD-2.0

|

JG-2.0

|

JG-2.0

|

JG-2.0

|

JG-3.0

|

JG-5.0

|

|

<300

|

BN-3.0

|

BN-3.0

|

JG-2.0

|

JG-2.0

|

JG-2.0

|

JG-4.0

|

JG-5.0

|

JG-5.0

|

|

<500

|

BN-3.0

|

JG-2.0

|

JG-2.0

|

JG-2.0

|

JG-3.0

|

JG-5.0

|

JG-6.0

|

JG-7.0

|

|

<1000

|

JD-2.0

|

JG-2.0

|

JG-2.0

|

JG-2.0

|

JG-4.0

|

JG-6.0

|

JG-7.0

|

JG-8.0

|

|

<2000

|

JG-2.0

|

JG-2.0

|

JG-3.0

|

JG-3.0

|

JG-5.0

|

JG-6.0

|

JG-8.0

|

JG-9.0

|

|

<3000

|

JG-2.0

|

JG-2.0

|

JG-4.0

|

JG-4.0

|

JG-6.0

|

JG-8.0

|

JG-9.0

|

|

|

<5000

|

JG-2.0

|

JG-2.0

|

JG-5.0

|

JG-5.0

|

JG-7.0

|

JG-8.0

|

|

|

|

<15000

|

JG-3.0

|

JG-3.0

|

JG-5.0

|

JG-8.0

|

JG-9.0

|

JG-9.0

|

|

|

|

<25000

|

JG-6.0

|

JG-7.0

|

JG-8.0

|

JG-9.0

|

|

|

|

|

|

|

Proper

Mixer Mounting and Positioning

|

|

|

|

|

|

|

|

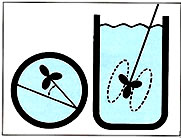

In

most applications involving small

mixing tanks of 1000 gallons or less, the

mixer is clamped to the side of the tank.

Optimum mixing will be achieved when

the mixer is angled from the tank wall,

either off center (figure 1) or on center

(figure 2). Improperly mounting a portable

mixer will greatly lessen mixing

efficiency, cause vibration and could

possibly damage the mixer.

Angling off center is preferred when

good material turnover is required, as in

mixing a slurry. Angling on center is desired

for more gentle mixing and when

vortexing must be minimized.

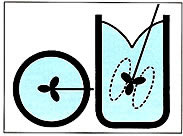

Larger size tanks may require that a

mixer be mounted directly in the center of

the tank with the shaft vertical (figure 3).

When a mixer is used in this arrangement,

baffles are recommended to prevent the

contents of the tank from turning in the

direction of the mix. If this occurs, mixing

action will be poor.

Such baffling will avoid vortexing and

allow mixing to be as thorough as possible.

These suggests that four baffles

be used, located 90° apart and sized

approximately 1/12 of the tank diameter.

The baffle should not fully extend to the

bottom of the tank and a gap should be

provided between the baffle and the

tank wall. |

|

|

|

|

|

|

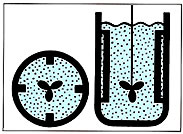

FIGURE

1 - Angling the portable mixer off center

is the position recommended for rapid turnover

of tank contents and good bottom washing. |

|

|

|

|

|

|

|

|

|

|

|

|

FIGURE

2 - On center angling will produce good

mixing with minimum vortexing. Tank contents

turn over thoroughly but gently. |

|

|

|

|

|

|

|

|

|

|

|

|

FIGURE

3 - For mixing in larger tanks, the mixer

is often placed vertically on center. In this con-

figuration, baffles are recommended to prevent

the contents of the tank from rotating, avoid

vortexing and achieve good mixing and top-to-

bottom turnover. |

|

|

|

|

Gear Driven Mixers,

Mixers and Agitators, Bung Mount, Drum Mixers, Drum Agitators,

Collapsible Propellers allow for

easy installation, Air, Electric, Variable-Speed, Explosion

Proof Motors, for use with closed top 55-gallon drums with

2" NPT

Bung, and C-Clamp Mount from your source for material handling

equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|