Back to Product Page

|

|

|

|

|

|

|

|

|

|

CONDUCTOR

BAR SELECTION

|

|

|

|

|

| Determining

Ampere Load |

|

|

|

|

The

conductor selected must be large enough to carry the

necessary ampere load safely without undue heating. To

compute the ampere load, proceed as follows: |

|

Heavy

Duty — Class D Crane Service Used continually

during the work day and usually for more than one shift.

Loads of 50% of rated capacity or more handled constantly

during the work period. Use a factor of 110% of the

calculated ampere load. |

1.

List the horsepower of all motors used in the

application. |

|

2.

Determine the voltage and type of current that will feed

the conductor. For example: 230v dc 2 wire;

460v ac 3

phase; etc. |

|

Severe

Duty — Class E and F Crane Service Handles

loads approaching 100% of the capacity all during the work

period and for more than one shift. This includes large,

heavy duty units such as bucket cranes, magnet lift cranes,

cement or steel handling cranes. Use a factor of 120% of

the calculated ampere load. Check the traveling speed of

the crane, as it may exceed the tracking capability of the

Figure 8 Conductor. |

3.

Refer to the Horsepower Conversion Table on page 3

and convert the horsepower to amperes. |

|

4.

Prepare the ampere load figure that will be used to size

the conductors as follows: |

|

|

List

the full load ampere rating of each motor used

on the crane or monorail unit. Determine the duty

cycle from the following paragraphs and apply the

corresponding factor. |

|

|

|

5.

If the conductors are to be located where the ambient

air temperature is unusually high, the current carrying

capacity of the conductor is reduced. Multiply the current

capacity of the selected conductor by the derating factor in

the following table. |

|

Light

Duty — Class A and B Crane Service

Standby or infrequent use. Up to two motors started

at a time. Two to five lifts per hour. Use a factor of

90% of the calculated ampere load. |

|

|

|

Temperature

Derating Table |

|

|

|

Ambient Air Temperature |

Derating Factor |

| 100°F |

95% |

| 130°F |

75% |

| 160°F* |

50% |

|

|

Average

Duty — Class C Crane Service

Moderate use during the work day. Five to ten lifts

per hour. Not over 50% of the lift at rated capacity.

Use a factor of 100% of the calculated ampere load. |

|

|

|

|

|

|

|

*At

this ambient temperature it will be necessary to use the higher

rated conductor cover, XHT rated at 280° F. |

|

|

|

| Determining

Voltage Drop |

|

|

|

According

to CMAA, the voltage drop to the unit motors

shall not be more than 3% from the power taps to the load

at the farthest point on the conductor run. To determine

the voltage drop use the appropriate formula in the

following table. |

|

See

Conductor Engineering Data Table on page 4 for

values of Z and R. |

|

Divide

voltage drop by system voltage to get the percent

of voltage drop. |

|

Maximum

voltage drops that are 3% of various supply

voltages are as follows: |

|

|

|

Current Type |

Formula |

| AC 3 phase

60 cycle |

V = L x

I x Z x 1.73 |

| AC 1 or

2 phase 60 cycle |

V = L x

I x Z x 2 |

| DC 2 wire

system |

V = L x

I x R x 2 |

|

|

|

|

|

|

Supply Voltage |

Voltage Drop (V) |

| 460v ac |

13.8 |

| 230v ac

or dc |

6.9 |

| 575v ac |

17.2 |

|

|

|

| V

= Voltage drop |

|

| L

= Distance from power feed to end of conductor |

|

Volts

lost that are equal to or less than the above values

when using the formulas above will help in selecting the

correct conductor. |

I

= Total amperes drawn as calculated from

conversion charts |

|

| Z

= ac impedance |

|

|

| R

= dc resistance |

|

|

|

|

|

|

|

|

|

| Conductor

Selection Example |

|

Horsepower

Conversion Table |

Given

a 300 foot runway, power fed at the center, using

460 volt, 3 phase, 60 cycle power supplied to a bridge

crane — there is a 40 h.p. hoist motor, a 20 h.p. bridge

motor, and a 5 h.p. trolley motor. The operation is Average

Duty. Ambient temperature varies from 50°F in winter to

90°F in summer on this Indoor installation. |

|

|

3

Phase AC - 60 Cycle

Amperes |

Direct

Current Amperes |

|

H.P. |

230v |

460v |

575v |

230v |

|

1/2 |

2 |

1 |

0.8 |

2.7 |

|

3/4 |

2.8 |

1.4 |

1.1 |

3.8 |

|

1 |

3.6 |

1.8 |

1.4 |

4.7 |

|

1 1/2 |

5.2 |

2.6 |

2.1 |

6.6 |

|

2 |

6.8 |

3.4 |

2.7 |

8.5 |

|

3 |

9.6 |

4.8 |

3.9 |

12.2 |

|

5 |

15.2 |

7.6 |

6.1 |

20 |

|

7 1/2 |

22 |

11 |

9 |

29 |

|

10 |

28 |

14 |

11 |

38 |

|

15 |

42 |

21 |

17 |

55 |

|

20 |

54 |

27 |

22 |

72 |

|

25 |

68 |

34 |

27 |

89 |

|

30 |

80 |

40 |

32 |

106 |

|

40 |

104 |

52 |

41 |

140 |

|

50 |

130 |

65 |

52 |

173 |

|

60 |

154 |

77 |

62 |

206 |

|

75 |

192 |

96 |

77 |

255 |

|

100 |

248 |

124 |

99 |

341 |

|

125 |

312 |

156 |

125 |

425 |

|

150 |

360 |

180 |

144 |

506 |

|

200 |

480 |

240 |

192 |

675 |

|

| Step

1 - Determining Ampere Load |

|

See

National Electric Code article 610-14(e)for

determining motor loads where there are multiple motors

on a single crane. Then from the Horse Power Conversion

Table 460v column (right): |

|

|

40

h.p. hoist motor — 52 amps @ 100% = 52 amps |

|

|

|

20

h.p. bridge motor — 27 amps @ 50% = 13.5 amps |

|

|

5

h.p. trolley motor — 7.6 amps @ 50% = 3.8 amps |

|

|

The

total current load is 69.3 amperes. |

|

|

With

Average Duty cycle, the current load is

factored at 100%. Normal ambient conditions of

50°F to 90°F require no temperature derating.

Selecting a 90 amp conductor caused a voltage

drop of 4.3% using the formula. Since this is

unsatisfactory, use a 110 amp conductor (FE-908)

for Step 2. |

|

| Step

2 - Determining Voltage Drop |

|

| Use

the AC 3 phase formula above. |

|

|

V

= L x I x Z x 1.73 where: |

|

|

L

= 150 ft. (Distance to the end of the runway from

the center power feed.) |

|

|

I

= 69.3 amperes |

|

|

Z

= .0008 for 110 amp conductor |

|

|

1.73

= 3 phase constant |

|

|

V

= 150 x 69.3 x .0008 x 1.73 |

|

|

|

=

14.4 volts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

14.4/460

= 3.1%

|

|

|

|

Since

this voltage drop only occurs at the farthest end

when two or more motors are started simultaneously,

exceeding the 3% voltage drop goal by only 0.1% will not

cause a problem. |

|

|

|

|

|

|

| Ampere

Load Calculations for Multiple Units |

|

The

voltages listed are rated motor voltages. The current

listed shall be permitted for system voltage ranges of 110

to 120, 220 to 240, 440 to 480, and 550 to 600 volts.

Motors rated at 208v ac should increase the 230 volt

column figures by 10%. |

For

information about sizing ampere loads for multiple

cranes on the same runway, see Article 610-14 (e) of the

National Electrical Code for the demand factors. This

article also covers additional loads on the bridge cranes

other than motor loads. |

|

|

For

motors that are wound for single or double phase

operation, use the nameplate rating. For older slip ring

motors or models that have secondary windings be sure to

obtain both primary and secondary current ratings.

Secondary windings may also need separate conductors

or cables when updating the electrification. |

| Induction

Type Squirrel Cage and Wound Rotor Motors |

The

Horsepower Conversion Table is taken from the 1996

NEC Article 430. The values are for motors running at

usual speeds with normal torque characteristics. Motors

built for especially low speeds or high torques may require

more running current, and multi-speed motors will have full-load

current varying with speed. In these cases, use

the higher nameplate current rating. |

|

|

|

|

|

Conductor

Engineering Data Table

|

|

Conductor Bar No. |

Description |

Weight per 10' section lbs. |

Ampere

Rating |

Coefficient of Linear Expansion per °F |

Resistance

Factor |

Circular Mills |

|

AC (z) ohms/ft. |

DC (R) ohms/ft. |

|

Continuous |

Intermittent* |

|

FE-908 |

Galvanized Steel |

6.5 |

110 |

165 |

0.000007 |

0.0008 |

0.0005 |

189,000 |

|

FE-1608 |

Stainless/Copper Laminate |

6.5 |

160 |

240 |

0.000008 |

0.000144 |

0.0001 |

188,000 |

|

FE-2008 |

Copper/Steel Laminate |

6.25 |

250 |

350 |

0.000008 |

0.000142 |

0.0001 |

189,000 |

|

FE-3008 |

Rolled Copper |

6.75 |

350 |

530 |

0.000009 |

0.000085 |

0.000058 |

188,000 |

|

FE-5008 |

Extruded Copper |

11.5 |

500 |

750 |

0.000009 |

0.000065 |

0.000033 |

315,000 |

|

| *Intermittent

Service Rating is determined for one minute on, one minute off

operation. |

| Miscellaneous

Applications |

|

|

|

| Curves |

|

The

minimum spacing between conductors on curves is

three inches. |

Duct-O-Bars,

except the Totally Enclosed System,

can be bent to form curved sections without damaging

the insulating cover or conductor. Bends with a five-

foot radius or greater can be done in the field by using

a fly wheel, monorail beam, or similar object to bend

the conductor to approximately the necessary radius.

Hangers used on curved sections must be placed at

intervals of 2-1/2 feet maximum— and closer if required.

Use B-100 cross bolt clamp type hangers and P-Series

collectors. |

|

|

For

curves of five-foot radius or more, use five-inch

collector shoes. For curves of less than five-foot radius

use three-inch collector shoes; also consult the factory for

additional information. |

|

|

|

|

|

| Discontinue

Circuits |

|

On

discontinuous circuits a pickup guide assembly must

be installed to ensure that the self-centering type collectors

engage and disengage the conductor bar. The pickup

guide (FE-2JNN3 is illustrated) must have its own support

point. |

|

|

| Interlocks,

Switches, or Fixed Gaps |

|

|

The

maximum fixed gap occurring at interlocks is one-inch

when using 100 amp P-Series collectors and 1/2 inch

when using 40 amp collectors. Use transfer caps as shown

to ensure that the collector brushes transfer evenly and

smoothly. Also round both ends of the contact brushes to

facilitate the transfer. Use clamp type hangers only. When

both interlocks and curves of less than a four-foot radius

are encountered, the tandem 40 amp collector is

recommended. |

|

| Other

Special Applications |

|

|

|

Consult

the factory for recommendations on applications

such as de-icing systems, totally enclosed systems, and

other systems not covered here. |

|

|

|

|

|

|

|

|

| Expansion

Gaps |

|

|

|

|

|

Expansion

gaps should be placed at intervals determined

by 1) the expansion rate of the metal in the conductor

selected, and 2) the variation in temperature that will

occur at the conductor location over a full year of operation. |

Example:

A 300' long copper conductor system (X)

installed outdoors with an anticipated temperature

fluctuation of 80°F (Y). |

|

Total

Expansion = 300'/100' x 80°F/100°F = 2.4". |

| 1.

Steel Conductor Systems |

|

3.

Determine the Number of Expansion Gap

Assemblies |

Given

that steel conductors expand 1" for every 150' of

runway with a temperature change of 100°F over a full

year of operation, put the length of the runway and the

maximum temperature change for the system to be used

into the following formula: |

|

After

calculating the actual expansion of the runway

conductor system, use the following rule of thumb to pick

the number of expansion gap assemblies: |

|

a.

Under 1" of expansion, use no expansion assemblies.

Install one anchor clamp set at the

center of the

conductor run. |

|

Total

Steel Expansion (inches) = X/150' x Y/100°F |

|

where

X is the runway length and Y is the 12 month

temperature variation. |

|

b.

From 1" to 2" of expansion, use one expansion

assembly in the center of the conductor

run. |

Example:

A 450' long steel conductor (X) installed in a

building with an indoor temperature change of 40°F (Y). |

|

c.

From 2" to 4" of expansion, use two expansion

assemblies. Locate them at 1/3 of the runway length in

from each end. |

|

Total

Expansion = 450'/150' x 40°F/100°F = 1.2". |

|

| 2.

Copper Conductor Systems |

|

d.

For systems with more than 4" of expansion, use one

expansion gap assembly for each 2" of expansion. |

Given

that copper conductors expand 1" for every 100' of

runway over a 100°F temperature change at the conductor

over a full year of operation, put the length of the runway

and the maximum temperature change for the system to

be used into the following formula: |

|

|

4.

Anchors |

|

Anchor

clamps are required at midpoint on all systems

without expansion gaps and halfway between gaps and

from gaps to the end of systems with multiple gaps. See

the Figure 8 Installation Instructions on anchor locations. |

|

Total

Copper Expansion (inches) = X/100' x Y/100°F. |

|

|

|

The

maximum gap opening for all ten foot Figure 8

expansion gap assemblies is 1-3/4 inches. |

|

Expansion

assemblies are also required at building

expansion joints. |

|

|

|

|

|

| Conductor

Assembly Selection |

|

Duct-O-Wire

Figure 8 Conductor Bars are furnished as assemblies consisting

of a ten-foot long conductor bar rated at

600 volts, an insulating cover, splice cover, and connector

pins or joint clamps as applicable. |

The

insulating cover must be appropriate for the environment —

indoor, outdoor, or high temperature — in

which the conductor is to operate. |

Indoor

systems are for use in ambient temperatures up to 160°F.

They have an Orange PVC Insulating Cover. They

are not recommended for outdoor use in direct sunlight. |

Outdoor

systems are for use in direct sunlight and ambient temperatures

up to 160°F. They have a Gray PVC

Insulating Cover with an ultraviolet additive. |

High

temperature systems are for use in ambient temperatures up to

280°F. They have a Yellow Lexan Insulating

Cover. |

From

the table to the right, you can select the basic (FE) conductor

assembly with the appropriate bar and insulating

cover for your application. |

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

| Pricing

for Basic Figure 8 (FE) Conductor Assemblies (10' Lengths) |

|

|

|

|

|

|

|

|

| Typical

Conductor Mounting |

|

|

|

|

|

|

|

|

|

|

|

|

| Note: |

|

indicates

minimum conductor spacing. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Standard

Vertical Mounted Conductors |

|

Lateral

Mounted Conductors |

|

| 3-Phase

System • Bottom Contact • 5 Ft. Maximum Support Spacing |

|

4

Ft. Maximum Support Spacing. |

|

|

|

|

|

Use

only Lateral (L) Model Collectors. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Monorail

Application |

|

|

Install

two conductors on one side of the beam and one conductor

on the opposite side to balance the collector spring forces,

particularly

on light weight hoists. |

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

|

|

|

| DUCT-O-BAR

FIGURE 8 (FE) COMPONENTS |

|

|

|

Model Number |

Weight

Pounds |

Description |

Price |

|

Angle

Brackets for Web Mounting

|

|

Brackets

are galvanized 12 gauge rolled steel channel.

Hangers are priced separately, but will be factory installed

at no charge

when hanger locations are shown on sketch.

|

|

B-100-BR1A |

1 |

Bracket - 11-1/4" long. |

$6.20

|

|

|

1.12 |

Bracket - 14-1/4" long. |

$8.40

|

|

|

1.18 |

Bracket with gusset support - 14-1/4" long. |

$10.00

|

|

|

1.5 |

Bracket - 20-1/4" long. |

$11.20

|

|

|

1.57 |

Bracket with gusset support - 20-1/4" long. |

$12.80

|

|

|

|

|

Model Number |

Weight

Pounds |

Description |

Price |

|

Straight

Brackets for Top Flange Mounting

|

|

Brackets

are galvanized 12 gauge rolled steel channel. Hangers

are priced

separately, but will be factory installed at no charge

when hanger locations are

shown on sketch.

|

|

B-100-BR3A |

1.25 |

Bracket - 18" long. |

$7.30

|

|

|

1.82

|

Bracket

with two Mounting Clamps

and hardware - 18" long

|

$14.50

|

|

|

1.32

|

Bracket

- 21" long

|

$8.40

|

|

|

2.01

|

Bracket

with two Mounting Clamps

and hardware - 21" long

|

$15.60

|

|

|

1.6

|

Bracket

- 24" long

|

$9.50

|

|

|

2.19

|

Bracket

with two Mounting Clamps

and hardware - 24" long

|

$16.70

|

|

|

8

|

Channel

- 10 feet long

|

$45.00

|

|

|

0.31

|

Universal

Mounting Clamps with hardware.

For 5/8" to 1-5/16" thick Beam Flanges.

|

$3.40

|

|

|

1.75

|

Capped

I-Beam Bracket with hardware. 18" long

|

$14.50

|

|

|

1.94

|

Capped

I-Beam Bracket with hardware. 21" long

|

$15.60

|

|

|

2.12

|

Capped

I-Beam Bracket with hardware. 24" long

|

$16.70

|

|

|

T-Brackets with Mounting Plate for Web Mounting |

|

Brackets

are primed 12 gauge rolled steel channel with mounting

plate

and hardware. Hangers are priced separately, but will

be factory installed at

no charge when hanger locations are shown on sketch.

|

|

B-100-BRCT1 |

1.2 |

Bracket - 2 holes - 3-3/4" long. |

$13.00

|

|

|

1.3 |

Bracket - 3 holes - 5-1/4" long. |

$13.50

|

|

|

1.5 |

Bracket - 4 holes - 6-3/4" long. |

$14.00

|

|

|

1.6 |

Bracket - 5 holes - 8-1/4" long. |

$14.50

|

|

|

1.7 |

Bracket - 6 holes - 9-3/4" long. |

$15.00

|

|

|

1.8 |

Bracket - 7 holes - 11-1/4" long. |

$15.50

|

|

|

1.9 |

Bracket - 8 holes - 12-3/4" long. |

$16.00

|

|

|

2 |

Bracket - 9 holes - 14-1/4" long. |

$16.50

|

|

|

2.1 |

Bracket - 10 holes - 15-3/4" long. |

$17.00

|

|

|

2.2 |

Bracket - 11 holes - 17-1/4" long. |

$17.50

|

|

|

2.3 |

Bracket - 12 holes - 18-3/4" long. |

$18.00

|

|

|

Z-Brackets for Lateral Mounted Conductors |

|

Brackets

are red primed 10 gage steel. Hangers are priced separately,

but will

be factory installed at no charge when hanger locations

are shown on sketch.

|

|

|

1.64

|

Z-Bracket

- 3" hanger spacing,

6" mounting hole spacing. O.A.L. - 7-1/2"

|

$20.00

|

|

|

1.8

|

Z-Bracket

with hardware - 3" hanger spacing,

6" mounting hole spacing. O.A.L. - 7-1/2"

|

$20.60

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

Model Number |

Weight

Pounds |

Description |

Price |

|

Snap-In Type Hanger Assemblies

|

|

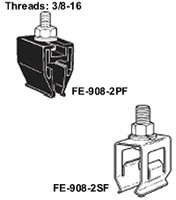

FE-908-2PF |

0.1 |

These hangers are not recommended for curves, switches

or short runs

unless separate anchors are used. Refer to the Figure

8 installation

Instructions.

|

|

Nylon Insulating Hanger. |

$1.70

|

|

FE-908-2PFS |

0.1 |

Nylon Insulating Hanger with Stainless Steel

Hardware. |

$3.40

|

|

FE-908-2SF |

0.11 |

DO NOT USE nylon hangers

in temperatures higher than

230°F. DO NOT exceed 4 lb. per foot torque when tightening

nut on mounting bolt.

|

|

Zinc Plated Steel Hanger. |

$1.70

|

|

|

Snap-In Type Spring Hanger and Insulator

Assemblies for Outdoor, Wet and Dirty Applications |

|

|

0.2

|

Zinc

Plated Steel Hanger with Insulator

|

$4.90

|

|

|

0.2

|

Epoxy

Coated Steel Hanger with Insulator

|

$6.00

|

|

|

0.2

|

Stainless

Steel Hanger with Insulator and Stainless Steel Hardware

|

$9.40

|

|

|

Clamp Type Hanger Assemblies for All Conductor Systems |

|

|

0.19

|

Zinc

Plated Steel Hanger

|

$2.50

|

|

|

Clamp Type Hanger and Insulator Assemblies

for Outdoor, Wet and Dirty Applications |

|

|

0.3

|

Zinc

Plated Steel Hanger with Insulator.

|

$6.00

|

|

|

0.3

|

Epoxy

Coated Steel Hanger with Insulator.

|

$7.70

|

|

|

0.3

|

Stainless

Steel Hanger with StainlessSteel Hardware.

|

$10.50

|

|

|

Snap-In Type Special Hanger Assemblies |

|

|

0.5

|

Plastic

Triple Hanger Assembly

|

$7.40

|

|

|

0.53

|

Zinc

Plated Steel Triple Hanger Assembly

|

$7.50

|

|

|

0.72

|

Zinc

Plated Steel Four-Gang Hanger Assembly

|

$10.40

|

|

|

0.93

|

Zinc

Plated Steel Five-Gang Hanger Assembly

|

$10.60

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

Model Number |

Weight

Pounds |

Description |

Price |

|

|

Power

Feeds with Insulating Case

|

|

|

0.26

|

110

Amp Rated - Copper. For FE-908-2 systems.

Will accept up to #2 AWG cable.

|

$13.40

|

|

|

0.63

|

250

Amp Rated - Bronze.For FE-1608-2 and FE-2008-2 systems.

Will accept up to #1/0 AWG cable.

|

$38.90

|

|

|

1.1

|

350

Amp Rated - Cast Bronze. For FE-3008-2

systems. Will accept up to #3/0 cable.

|

$58.00

|

|

|

End Power Feeds |

|

|

0.14

|

40

Amp Rated. For all systems with FE-908,

FE-1608, FE-2008, and FE-3008 conductor bar.

|

$8.40

|

|

|

Expansion Gap Assemblies |

|

Each assembly consists of a ten-foot conductor bar,

insulating cover, connector pins for one end, guide

assembly,

two power feeds with a jumper cable and hanger set.

Refer

to the Figure 8 Installation Instructions.

|

|

|

9

|

For

Indoor System FE-908-2.

|

$134.00

|

|

|

9

|

For

Outdoor System FE-908-2-SC.

|

$140.00

|

|

|

9

|

For

High Temperature System FE-908-2XHT.

|

$145.00

|

|

|

10.5

|

For

Indoor System FE-1608-2.

|

$334.00

|

|

|

10.5

|

For

Outdoor System FE-1608-2-SC.

|

$350.00

|

|

|

10.5

|

For

High Temperature System FE-1608-2XHT.

|

$360.00

|

|

|

10

|

For

Indoor System FE-2008-2.

|

$330.00

|

|

|

10

|

For

Outdoor System FE-2008-2-SC.

|

$345.00

|

|

|

10

|

For

High Temperature System FE-2008-2XHT.

|

$355.00

|

|

|

12.5

|

For

Indoor System FE-3008-2.

|

$356.00

|

|

|

12.5

|

For

Outdoor System FE-3008-2-SC.

|

$372.00

|

|

|

12.5

|

For

High Temperature System FE-3008-2XHT.

|

$378.00

|

|

|

Special Application Components |

|

|

3.75

|

Pickup

Guide Assembly - 3" wide. Includes

clamps and two foot section of system conductor.

Specify conductor system.

|

$134.00

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

Model Number |

Weight

Pounds |

Description |

Price |

|

|

Special

Application Components (cont.)

|

|

|

0.08

|

Transfer

Cap. For FE-908, FE-1608, FE-2008,

and FE-3008 Bar.

|

$4.50

|

|

|

0.08

|

Transfer

Cap. For FE-908, FE-1608, FE-2008 and

FE-3008 Bar. Cut at 45° for left hand curves.

|

$7.30

|

|

|

0.08

|

Transfer

Cap. For FE-908, FE-1608, FE-2008, and

FE-3008 Bar.Cut at 45° for right hand curves.

|

$7.30

|

|

|

0.02

|

Isolating

Piece - 1" long. For all bars except

FE-758 and FE-5008

|

$2.80

|

|

|

0.19

|

Isolating

Piece - 8" long. For all bars except

FE-758 and FE-5008

|

$7.80

|

|

B-100-TG

|

1.81

|

Steel

Transfer Guide Assembly.

For use with isolating pieces.

|

Upon

Request

|

|

B-100-TGE

|

1.81

|

Epoxy

Coated Transfer Guide Assembly.

For use with isolating pieces.

|

Upon

Request

|

|

|

C-Series Collector Assemblies |

|

C-Series

Collectors are used on short continuous run systems.

They feature steel pivot points for good tracking capability.

|

|

C-40-V3 |

1.5 |

40 Amp Collector - single shoe.

Vertical mount. |

$67.00

|

|

|

2.75

|

40

Amp Collector - single shoe. Lateral mount

with steel counter weight. O.A.L. - 15"

|

$78.00

|

|

|

1.8

|

100

Amp Collector - single shoe. Vertical mount.

|

$82.50

|

|

|

3.13

|

100

Amp Collector - single shoe. Lateral mount

with steel counter weight. O.A.L. - 16"

|

$100.00

|

|

|

|

|

Collector Mounting Post |

|

|

3.25

|

Mounting

Post with Hardware - 18" long.

Mounting plate is 4" square with 3" hole

spacing for C-Series and P-Series Collectors.

(Contact us for special lengths or finishes.)

|

$49.50

|

|

|

P-Series Collector Assemblies |

|

P-Series

collectors are used on straight and curved runs and

transfers.

The pantograph design provides virtually constant spring

pressure for the

entire stroke range. Lateral Mount Collectors are provided

with spring balance.

Conductor Bars must be spaced at least 3 inches apart.

|

|

P-40-V3 |

2.19 |

40 Amp Collector - single shoe. Vertical mount. |

$72.50

|

|

|

2.5

|

40

Amp Collector - single shoe. Lateral mount.

|

$78.00

|

|

|

2.25

|

40

Amp Collector - single shoe. Self-centering.

|

$94.50

|

|

|

2.44

|

100

Amp Collector - single shoe. Vertical mount.

|

$88.00

|

|

|

2.55

|

100

Amp Collector - single shoe. Lateral mount.

|

$99.00

|

|

|

2.6

|

100

Amp Collector - single shoe. Self-centering.

|

$110.00

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

Model Number |

Wgt.

Lbs. |

Description |

Price |

|

|

P-80-VT3 |

4.34 |

P-Series

Collector Assemblies (cont.)

|

80 Amp Collector - double shoe.

Vertical mount. |

$131.00

|

|

|

4.35

|

80

Amp Collector - double shoe.

Lateral mount.

|

$143.00

|

|

|

4.5

|

80

Amp Collector - double shoe.

Self-centering.

|

$154.00

|

|

|

5

|

200

Amp Collector - double shoe.

Vertical mount.

|

$160.00

|

|

|

4.63

|

200

Amp Collector - double shoe.

Lateral mount.

|

$171.00

|

|

|

4.6

|

200

Amp Collector - double shoe.

Self-centering.

|

$194.00

|

|

|

Additional Components |

|

|

0.03

|

Spring

Cover Clip - Zinc Plated Steel.

Used only to ensure alignment of the

cover on laterally mounted systems.

Placed midway between hangers.

|

$1.20

|

|

|

0.3

|

Clamp

Hanger Set - 2 pieces.

Clamps both sides of hanger.

|

$6.70

|

|

|

0.04

|

Flexible

PVC End Cap.

For all Figure 8 conductor bars.

|

$1.20

|

|

|

2.88

|

Connector

Tool. One tool usually ordered

for each new system. Used to pull two

sections of bar together.

|

$22.20

|

|

|

0.1

|

Connector

Tool Pins - Pair.

|

$5.60

|

|

|

0.05

|

Splice

Cover - Standard black. Use this part number when ordering

extra splice covers.

|

$1.20

|

|

|

Conductor

Bar Cleaning Accessories |

|

C-100-VCT |

1.8 |

Contact

us for application.

|

Complete C-Series Collector with

cleaning head. Vertical mount. |

$93.50

|

|

|

2.19

|

Complete

P-Series Collector with cleaning head. Vertical mount.

|

$99.00

|

|

|

0.17

|

Series

C & P Contact Shoe with

Self Cleaning Inserts - 3"L x 1/4"W

|

$20.00

|

|

|

0.26

|

Series

C & P Contact Shoe with

Self Cleaning Inserts - 5"L x 1/4"W

|

$31.10

|

|

|

0.14

|

Cleaning

Brush - Stainless Steel.

|

$37.80

|

|

|

|

|

DUCT-O-BAR

|

|

|

|

|

|

|

SPECIAL

APPLICATION CONDUCTORS

|

|

|

|

|

|

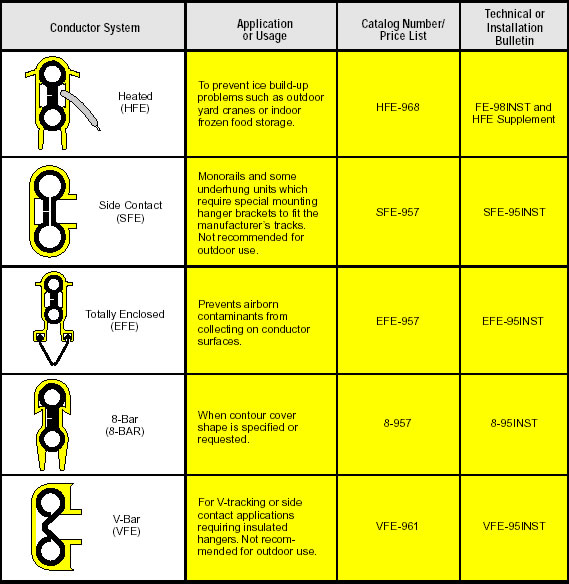

All

Duct-O-Wire Figure 8 conductor systems can be sized electrically

by using the general and technical

information contained in this brochure. For applications with

special mechanical or environmental considerations,

refer to the table below for the proper Duct-O-Bar System to

use. |

|

|

|

|

|

|

|

|

|

| PRICE

UPON REQUEST |

|

Conductor Systems,

Duct-O-Wire Festoon Electrification, Conductor Bar, Duct-O-Wire,

and Duct-O-Bar from your

complete source for material handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|