Back to Product Page

|

ENERGY-EFFICIENT

INSECT

ELECTROCUTORS

|

|

|

|

VERTICAL

WALL MOUNT SERIES 9 & 11

|

|

|

|

|

|

|

|

|

|

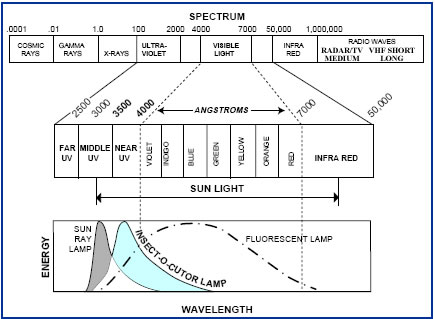

Most

flying insects are phototropic (attracted to light).

Specifically, houseflies and other nuisance flying

insects are highly attracted to light energy in the near

ultraviolet (black light) spectrum. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Wavelengths

between 330 and 360 Nanometers

provide the best attraction. These wavelengths are

neither visible nor harmful to human... but are

extremely visible and attractive to flying insects. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

Insect-O-Cutor® method uses an ultrahigh

intensity (UHI™) black light source to attract flying

insects to an electrified grid where they are killed

upon contact. The dead insects are then collected

in a drawer or tray for periodic inspection and disposal. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Designed

for high-traffic areas, typical Vertical

Wall Mounted Model installations include

personnel doors, loading dock areas, along

corridors, at firewall breaks, and at virtually all

exterior access points. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series

11

|

|

|

|

Series

9

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TECHNICAL DATA AND ELECTRICAL SPECIFICATIONS

|

ENERGY

EFFICIENT

(EE) MODELS |

|

|

|

|

|

|

|

|

|

|

|

120

VOLT/60 HZ MODELS

|

|

|

|

220

VOLT/50 HZ MODELS

|

|

are

designed to comply with

various energy compliance acts

and energy conservation

programs. Electronic-ballasted

models reduce overall electrical

consumption, while increasing

light output by 8% to 15% per

lamp due to increased operational

efficiency. Less energy consumed…

more insect attraction light emitted. |

|

| PRIMARY:

120 VOLTS, 60 HERTZ |

PRIMARY:

220 VOLTS, 50 HERTZ |

|

| SECONDARY:

4500 VOLTS |

SECONDARY:

5000 VOLTS |

|

|

NOTE: UNIT MUST BE GROUNDED.

|

|

|

|

|

|

|

|

|

|

|

TRANSFORMER

(WITH INTERNAL

CAPACITANCE): T740C |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TRANSFORMER

(WITH INTERNAL

CAPACITANCE): T1040C-2 |

|

mA

OUTPUT: 9.8

AMP. INPUT -

EE MODELS: 1.4-1.5 |

|

|

|

|

|

|

|

mA

OUTPUT............... 10.0

AMP. INPUT .............. 0.40 |

|

|

|

|

|

|

|

|

UNIVERSAL

VOLTAGE BALLAST —

(ONE PER UNIT): ..............BPU |

|

|

|

HIGH

PERFORMANCE BALLAST —

ONE OF EACH LAMP: |

|

|

|

|

|

|

|

|

| PRIMARY:

......................BP18 (SERIES 9) |

|

|

|

|

|

|

|

| AUXILIARY:

: ................N/A (SERIES 9) |

|

|

|

|

|

|

|

|

STANDARD

FEATURES: |

|

| PRIMARY:

......................BP48 (SERIES11) |

|

|

| AUXILIARY:

: ............... BA48 (SERIES 11) |

|

|

|

Rear

keyhole slots for wall mounting. Safety guard; safety switch

interrupts electrical current when servicing unit; internal

metal insect

collection drawer; spring-loaded and fixed lampholder sets for

simple

lamp installation; reflector panel increases black light emission…

three-

wire grounded cord and plug. 120Volt Models are safety-tested

and

certified by Intertek Testing Services, N.A. Inc. (ETLcm). |

|

|

|

|

ENERGY

EFFICIENT BALLASTS —

ONE PER UNIT: BPE18 (SERIES 9) |

|

|

ENERGY

EFFICIENT BALLASTS —

ONE PER UNIT: BPE24/48-2 (SERIES 11) |

|

|

|

|

|

PACKED

CARTON: 6.6 CUBIC FEET /

0.18 CUBIC METERS (SERIES 11) |

|

|

PACKED

CARTON:3.4 CUBIC FEET /

0.10 CUBIC METERS (SERIES 9) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Model No. of the item

you wish to purchase.

|

|

|

|

|

PRICING

FOR SERIES 9

|

|

Model No. |

Black Light

Attraction Lamps |

Unit Dimensions

W x H x D |

Shipping

Weight (lbs.) |

Metal Materials |

Price |

| 994EDG |

18 and 18B |

13.25" x 27" x 5.25" |

25 |

Sand Beige Textured |

$1,424

|

| 994EDGA |

18 and 18B |

13.25" x 27" x 5.25" |

25 |

Aluminized Steel |

$1,424

|

| 994EDGS |

18 and 18B |

13.25" x 27" x 5.25" |

28 |

Stainless Steel |

$1,811

|

|

|

|

|

|

|

PRICING

FOR SERIES 11

|

|

Model No. |

Black Light

Attraction Lamps |

Unit Dimensions

W x H x D |

Shipping

Weight (lbs.) |

Metal Materials |

Price |

| 1199EDG |

48 and 48B |

16.25" x 60" x 7.25" |

66 |

Sand Beige Textured |

$2,374

|

| 1199EDGA |

48 and 48B |

16.25" x 60" x 7.25" |

66 |

Aluminized Steel |

$2,374

|

| 1199EDGS |

48 and 48B |

16.25" x 60" x 7.25" |

73 |

Stainless Steel |

$3,124

|

|

|

|

|

|

|

EXPLANATION

OF INSECT-O-CUTOR® MODEL SUFFIXES:

|

|

|

|

|

| E

= ENERGY-EFFICIENT |

D

= INTERNAL COLLECTION DRAWER |

G

= SAFETY GUARD |

A

= ALUMINIZED STEEL

CONSTRUCTION |

S

= STAINLESS STEEL CONSTRUCTION |

T

= EXTERNAL COLLECTION TRAY |

| R

= RECESSED MODEL |

|

|

|

|

Frequently

Asked Questions

|

|

|

|

|

|

|

|

|

What

types of insects are attracted to Insect-O-Cutors? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

There

are very few types of flying insects which are not attracted

by near-ultraviolet light.

Thus, there are very few flying insects which are not attracted

to Insect-O-Cutors. |

|

|

|

|

|

|

|

|

|

How

large an area will an Insect-O-Cutor cover? |

|

|

|

|

|

|

|

|

|

|

|

|

|

Coverage

by a particular model depends upon many factors. Among these

factors are: types

of insects; competing light and other attractions; air temperature

and movement. A general rule

of thumb is to locate Insect-O-Cutors so that insects need not

be attracted more than 35 to 40 feet. |

|

|

|

|

|

|

|

|

Do

Insect-O-Cutors meet O.S.H.A. requirements? |

|

|

|

|

|

|

|

|

|

|

|

Yes,

when installed in accordance to Insect-O-Cutor recommendations

and specifications, and

in compliance with governing authorities, bureaus and agencies.

(In the U.S., refer to the current

edition of the National Electrical Code (NEC). |

|

|

|

|

|

|

|

|

What

is the life of an Insect-O-Cutor unit? |

|

|

|

|

|

|

|

|

|

|

|

Fifteen,

twenty or more years... with proper maintenance. |

|

|

|

|

|

|

|

|

Is

black light dangerous? |

|

|

|

|

|

|

|

|

|

|

|

The

near-ultraviolet light lamps used in Insect-O-Cutors peak at

357 Nanometers which is a

wavelength that is normally harmless to humans. This is a question

often asked because a number

of people have heard of ultraviolet "germicidal" lamps

used in air sterilization, purification and

disinfection fixtures. |

|

|

|

|

|

|

|

|

During

what hours should Insect-O-Cutors operate? |

|

|

|

|

|

|

|

|

|

|

|

Insect-O-Cutors

should be allowed to operate twenty-four hours a day, seven

days a week,

during the flying insect season. |

|

|

|

|

|

|

|

|

How

long will the black light lamps last in an Insect-O-Cutor? |

|

|

|

|

|

|

|

|

|

|

|

Although

the lamps will continue to light for several years in many instances,

emission levels of near-

ultraviolet light will drop below acceptable levels after approximately

seven months of use. It is

strongly recommended by Insect-O-Cutor as well as the lamp manufacturers

that lamp replacement

be made on an annual basis. |

|

|

|

|

|

|

|

|

Is

there much maintenance required? |

|

|

|

|

|

|

|

|

|

|

|

Other

than lamp replacement (which should be performed at least annually),

Insect-O-Cutors

should be cleaned periodically. This constitutes brushing debris

from the grid kill area, emptying

the collection drawers, and wiping exterior surfaces with a

dampened cloth. |

|

|

ABOUT

BLACK LIGHT

|

|

|

|

|

|

|

|

| LIGHT

AND THE SPECTRUM |

|

HEALTH

AND SAFETY ISSUES |

|

|

|

|

|

|

|

Insect

attraction lamps, like all lamps, emit energy in

the form of light. This energy is measured in wavelengths.

By determining wavelength measurements,

classification of different light types within the full light

spectrum is possible. |

|

The

primary health concerns most often associated

with ultraviolet light relate to skin irritation (erythema)

and eye irritation (conjunctivitis). Such irritations might

occur when an individual is exposed to light energy

emitted under 3200 nanometers. |

|

|

|

|

|

|

|

Some

types of light energy classifications include:

InfraRed, Visible (sunlight), and Ultraviolet [UV]. |

|

Lamps

emitting energy below this wavelength are

within the Middle UV and Far UV ranges — and are

commonly referred to as “tanning lamps” and

“germicidal” lamps, respectively. |

|

|

|

Ultraviolet

energy is measured and defined by light

within a band between 4000 and 1000 Angstroms (400

and 100 nanometers). Within this band of the light

spectrum, ultraviolet energy is further classified into

four sections: Near UV [UVA], Middle UV [UVB], Far

UV [UVC] and Vacuum UV. |

|

|

|

|

|

|

|

Insect-O-Cutor®’s

Gold Label™ insect attraction lamps

emit light energy at 365 nanometers (UVA). |

|

|

|

|

|

|

While

UVA energy is well above the harmful UVB

range of energy (320 nanometers), certain thresholds

of exposure to UV light sources have been established

by OSHA to ensure personnel safety as related below: |

|

|

|

Insect-O-Cutor®

insect attraction lamps emit light energy

within the Ultraviolet band of the light spectrum, specifically

light in the Near UV range. |

|

|

|

|

|

|

|

|

|

|

|

|

|

This

range of energy

is measured by wavelengths

between 400

and 350 nanometers. |

|

|

|

|

|

150,000

hours — |

|

|

|

of

continuous exposure

at a distance of twenty

feet (20') or 6.1 meters

from a light source; |

|

|

|

Regarding

flying insect

attraction, UVA

energy is most effective

at 365 nanometers.

This particular wave-

length is commonly

referred to as Black

Light. |

|

|

|

1,500

hours — |

|

of

continuous exposure

at a distance of six

feet (6') or 1.83

meters from a light

source; |

|

|

|

Forty

(40) hours — |

|

of

continuous exposure

at a distance of one

foot (.3048 meter)

from a light source. |

|

|

BLACK

LIGHT (BL)

AND BLACK

LIGHT BLUE

(BLB) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The

BL lamp produces most of its energy in the Near

UV range. However, a portion of the energy is outside the

UV range as the light spectrum enters the Visible Light

range. Note in the graph that visible light ranges from

Violet to Red. The lesser portion of the energy emitted

by the BL lamp is in the Blue Visible range. [This is what

we humans see as visible light.] |

|

|

|

|

|

SOURCES:

General Electric Lighting Company; Philips

Lighting; Sylvania GTE Products;

New England Journal of Medicine; Occupational

Health and Safety Administration (OSHA). |

|

|

|

|

|

|

|

|

|

|

|

The

BLB lamp produces its energy in the same

wavelength range that the BL lamp does. However,

the BLB lamp is constructed of special filtering

glass which reduces the passage of energy in the

visible light range between 4000 and 4600 Angstroms

(400 to 460 nanometers). |

|

|

|

|

|

|

|

|

|

|

Because

of this filtering of blue visible light, the lamp

does not have the light blue color that the BL lamp

does but instead appears as a blue/black color. |

|

|

|

INSTRUCTION

AND

MAINTENANCE MANUAL

|

|

|

|

| SAFETY

PRECAUTIONS — READ THIS SECTION FIRST |

|

|

|

| CAUTION |

HIGH

VOLTAGE, DISCONNECT BEFORE SERVICING. |

|

|

|

| CAUTION |

TO

REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, USE INDOORS ONLY

—

SEE INSTRUCTIONS. This product is intended for use indoors

only. To avoid risk

of fire or electric shock, do not use where it may be exposed

to direct water or direct sunlight

including roofed but open porches. |

|

|

|

|

| CAUTION |

NEVER

INSTALL INSECT-O-CUTOR® (IOC®) EQUIPMENT NEAR EXPLOSION

HAZARDOUS AREAS. (Areas defined as Class I, II or III —

See the Code of Federal Regulations). |

|

|

|

|

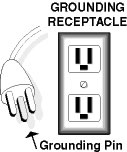

| CAUTION |

TO

PROVIDE CONTINUED PROTECTION AGAINST THE RISK OF ELECTRIC

SHOCK CONNECT TO PROPERLY GROUNDED OUTLETS ONLY. For your

safety,

consult a qualified electrician or serviceman if the grounding

instructions are not completely

understood, or if doubt exists as to whether the unit has been

properly grounded. |

|

|

|

|

| CAUTION |

TO

REDUCE THE RISK OF FIRE, REMOVE THE DEAD INSECTS

FREQUENTLY. See “Preventative Maintenance Program”

below. |

|

|

|

|

| CAUTION |

Use

extension cord marked SJW-A, SJEW-A, or SJTW-A only. Use only

three-wire extension

cords which have 3-prong plugs and 3-pole receptacles which

accept the attachment plug. Replace

or repair damaged cords. |

|

|

|

|

| CAUTION |

The

electrical rating of the extension cord must be as great as

the electrical rating of the product.

DO NOT ABUSE THE CORD. Never carry an Insect-O-Cutor®

by its cord or yank the

cord to disconnect it from the receptacle. Keep the cord from

heat, oil, and sharp edges. Any frayed

or worn cord should be repaired or replaced at once. |

|

|

|

|

| Contains

Mercury, Dispose According to Local, State or Federal Laws |

|

|

|

|

DISCONNECT

THE PRODUCT FROM THE POWER SUPPLY when not

in use; before servicing; when changing black light lamps;

cleaning; and the like.

Do not insert foreign objects into an IOC® product.

|

|

|

|

|

|

|

|

|

|

|

|

|

GENERAL

LOCATION RECOMMENDATIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

PRIOR

TO INSTALLING THE UNIT(S), PLEASE READ “ASSEMBLY AND

INSTALLATION

INSTRUCTIONS”: BELOW

|

|

|

|

|

|

|

|

|

|

|

|

An

Insect-O-Cutor® (IOC®) system may consist

of a single unit protecting a small area or many units

protecting an entire facility. A single unit can be

properly located/positioned by following our

general positioning recommendations. A multiunit

system may require the assistance of an

IOC® Systems Design Engineer or an authorized

representative. |

2.

HANGING UNITS NEAR OUTSIDE ENTRY POINTS |

|

|

|

|

|

|

|

|

FOR

DAY-SHIFT OPERATIONS

|

|

|

Locate

Unit

Parallel to the Door

|

|

|

Position

units broadside to the

area to be protected, or to the

exterior doors so that black light

attraction will face these insect

entry points. |

|

|

|

|

|

|

|

|

|

|

|

If

an IOC® survey proposal has been provided,

follow the instructions for exact positioning of the

units. If a survey proposal with location instructions

was not provided, adhere to the following

general guidelines. |

|

|

|

|

|

|

|

|

|

|

FOR

MULTI-SHIFT

OPERATIONS

|

|

|

|

|

|

Locate

Unit

Perpendicular to the Door

|

|

|

|

|

|

|

| 1.

LOCATION — ALL MODELS |

|

|

If

the exterior doors will be open

for prolonged periods during

hours of darkness, units should be

positioned at a 90° angle to the

doors. |

|

|

|

|

|

|

|

a)

Choose a location that will provide interception

of flying insects between the point of entry

into the

building and critical contamination areas

(use at

least one unit for each entry point). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b)

Place the unit a minimum of 10 to 15 feet (3-5

meters) from any exterior opening to minimize

the possibility of emitting insect attraction

light

out of any exterior opening. |

|

|

|

|

|

|

| 3.

GENERAL INFORMATION |

|

|

|

|

|

|

|

DO

NOT PUT THE IOC® UNIT WHERE YOU

“DO NOT WANT THE INSECTS”. For instance, do not

put an IOC® unit on the far side of a production line or

other point of possible contamination, in relation to

the point of entry. |

|

|

|

|

|

|

c)

Install the unit a minimum of 10 feet (3 meters)

from highly reflective surfaces. |

|

|

|

|

|

|

d)

Avoid setting unit near air currents from fans,

ducts, heat vents or other air movers. |

|

|

|

|

|

|

|

Locate

the unit between the product and the insect

entry point to intercept insects or lure insects from

critical areas. |

|

|

|

|

|

|

e)

Avoid placing equipment near high intensity

artificial light that might compete with

the unit’s black light attraction lamps. |

|

|

|

|

|

|

|

|

f)

REMEMBER: The process of insect

electrocution creates an electrical arc.

Contact Insect-O-Cutor® or one of its

representatives for assistance regarding

location of units in questionable areas. |

|

|

|

|

|

CAUTION:

|

|

|

NEVER

LOCATE A UNIT IN AN

EXPLOSION HAZARDOUS AREA.

|

|

| |

Examples:

Near areas where bulk flour,

sugar, grains, and other fine particles

(including dust) are present and/or airborne

in proximity to flammable gases,

oils, chemicals, and other igneous liquids;

near battery chargers; in surgical suites

and other medical areas where explosive

or flammable/combustible anaesthetic

agents are used. |

|

|

|

|

|

|

|

|

|

|

For

maximum flying insect elimination, an IOC® System should

consist of Three Phases. Phase I units intercept insects at

immediate points of entry. |

|

|

|

|

|

|

|

|

|

|

Phase

II units, located between entry points and critical interior

areas, intercept insects at such places as firewall breaks and

along corridors. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Phase

III units provide the final line of interception. In some

situations, units may be located within the critical area. [Critical

areas are those in which the least amount of flying insects

should

be found, if any.] |

|

|

|

|

|

|

|

|

|

ASSEMBLY

AND INSTALLATION

|

|

|

|

|

|

|

|

|

HANGING/OVERHEAD

SUSPENDED MODELS

|

|

WALL

MOUNTED MODELS

|

|

|

|

|

|

|

|

|

SERIES

312, 372, 389, 399, 492,

494, 589, 599, 2489, 2499, 3692,

3694, 4889, 4899, AND 894

|

|

|

|

|

|

|

|

|

SERIES

372, 812, 994, 6192, 6199, 1192, 1199,

7194, 1890, 1894, 2489, 2499, 2591, 2594,

2599, 3692, 3694, 4889, 4899, AND 894

|

|

|

|

|

|

|

|

|

|

|

|

| A.

Remove unit from carton; discard packing materials. |

|

A.

Remove unit from carton; discard packing materials. |

|

|

|

|

|

|

|

A.1

Series 372, 894, 2489, 2499, 3692, 3694, 4889,

and 4899 |

|

B.1

ASSEMBLY — Series 812, 994, 6192, 6199,

1192, 1199, 7194, 1890,

1894, 2591, 2594,

and 2599 |

|

These

models may be either overhead suspended or

wall mounted. To install as a hanging unit, remove

the optional reflective backplate accessory. The

backplate is required when wall mounting the unit . |

|

|

|

Units

are shipped completely assembled. An insect

collection drawer is packed inside each unit. |

|

|

|

|

|

|

|

B.2

ASSEMBLY — Series 372, 894, 2489, 2499,

3692, 3694, 4889, and 4899 |

|

|

|

|

B.

Screw the provided eyebolts through the threaded

holes located on the body of the unit

as shown

below: |

|

|

|

|

|

|

|

|

These

series models may be wall mounted or

overhead suspended. For wall mount installations,

an optional backplate is provided with each unit.

Do not remove this backplate; it is an essential part

when the unit is wall mounted. An insect collection

drawer is packed inside each unit. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C.1

INSTALLATION — Series 812, 994, 6192,

6199, 1192, 1199, and 7194 |

|

|

|

|

|

|

Recommended

mounting is to secure the unit to a

wall or pillar. Generally, the bottom of the unit should

be no lower than 18 inches (47 centimeters) from the

floor, and the center of the unit should not exceed

five [5] feet (1.5 meters) above the floor. The unit

should be attached to a vertical surface by inserting

lag bolts or screws through the keyshaped mounting

holes in the rear of the unit after properly inserting

and securing the lag bolts or screws into the wall/pillar. |

|

|

|

|

|

Make

certain the eyebolts are threaded properly into

the locknuts to ensure a secure hold. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C.

Attach the required length of chain or cable to each

eyebolt (using an “S” hook).

Caution: Use a

minimum 200 Lb. (90 to 100 Kg) test

“S” hook, chain

or cable. |

|

|

|

|

C.2

INSTALLATION — Series 372, 2489, 2499,

3692, 3694, 4889, 4899,

894, 1890, 1894, 2591,

2594 and 2599 |

|

|

|

|

|

These

series models may be used as free standing

units on or under counters, tables, benches or

shelves that adequately support the unit’s weight. |

|

|

|

|

|

|

D.

Attach the “S” hooks and chain or cable to the

ceiling,

roof truss, beam or bracket which has adequate

strength to support the weight. When the chain (or

cable) has been attached, test it for supportability of

the product weight before hanging the unit. |

|

|

|

|

|

|

|

Note:

For security purposes, it is recommended

that the unit be permanently affixed to a wall, pillar,

or other vertical surface. |

|

|

|

|

|

|

|

|

PORTABLE

SERIES 372, 2489, 2499,

1890, 1894, 2591, 2594 AND 2599

|

|

|

|

|

|

|

|

|

|

The

unit should be attached to a vertical surface by

inserting lag bolts or screws through the keyshaped

mounting holes in the rear of the unit after properly

inserting and securing the lag bolts or screws into

the wall. |

|

|

|

|

|

|

|

These

models, equipped with a carrying handle and

protective footpegs, may be used to provide spot

protection in temporary areas or as a monitor in

specific problem areas. It is not necessary to remove

the carrying handle should you elect to permanently

install the unit. Simply install the unit according to

the appropriate instructions. |

|

|

|

|

|

|

|

|

|

Designated

as “low headroom”, these horizontally

configured models are ideal for use in areas where

ceiling heights are limited or where vertical wall

space is at a premium. Units may be installed

securely over doorways. |

|

|

|

|

|

|

|

|

|

|

|

ALL

MODELS: HANGING/OVERHEAD SUSPENDED AND WALL MOUNTED

|

|

|

|

|

|

CONNECTING

UNITS TO POWER SOURCE:

|

|

|

|

|

| AFTER

INSTALLING THE UNITS — |

|

|

|

|

|

PLUG

INTO A STANDARD 110/120V, 60 HZ POWER SUPPLY. UNITS MUST BE

GROUNDED.

|

|

|

|

|

This

product is equipped with an NRTL approved

three-conductor cord and three-prong grounding

type plug to fit the proper grounding type receptacle. |

|

If

necessary, use extension cords marked SJW-A,

SJEW-A, or SJTW-A only. Use only 3-wire extension

cords which have 3-prong grounding-type plugs and

3-pole receptacles which accept the Insect-O-

Cutor® plug. Replace or repair damaged cords. |

|

|

|

To

reduce the risk of an electric shock, the plug must

be plugged into an appropriate outlet that is properly

installed and grounded. |

|

|

|

|

The

electrical rating of the extension cord must be as

great as the electrical rating of the product. Refer to

the unit’s electrical rating label. |

|

|

|

| FOR

YOUR SAFETY: |

|

|

|

Consult

a qualified electrician

or serviceman if the grounding instructions are not completely

understood … or if doubt exists

as to whether the unit has been

properly grounded. |

|

|

|

|

DO

NOT ABUSE CORD. Never carry an IOC®

product by the cord or yank the cord to disconnect it

from a receptacle. Keep the cord away from heat, oil,

and sharp edges. Any frayed or worn cord should be

repaired or replaced at once. |

|

|

|

|

|

|

|

Disconnect

the product from the power supply when

not in use, before servicing, when changing lamps,

cleaning, and the like. |

|

|

|

|

|

|

|

INSECT-O-CUTOR®

DESIGN FEATURES

|

|

|

|

| SAFETY

INTERRUPT SWITCH |

|

SAFETY

GUARD FLANGE

|

|

|

|

Partial

or complete removal of the guard will activate

the safety interrupt switch; electrical current to the

unit will be automatically shut off. Electrical current

will remain off until the guard has been replaced in

its original seated position on the unit’s bodyframe. |

|

Series

3692, 3694, 4889, 4899, and 894 are equipped

with a metal safety guard flange to act as a retainer

which allows authorized personnel to prop the guard

open for maintenance/service. |

|

|

|

BLACK

LIGHT LAMPS

|

|

|

|

|

|

|

PROTECTIVE

GUARDS

|

|

|

|

IOC®

units are shipped with the lamps in place. Certain

models are shipped with cardboard lamp supports to

prevent breakage in transit; remove and discard these

lamp supports prior to use. |

|

|

The

front guard on hanging/overhead suspended

models and the entire guard panel of wall mount

models must fit snugly to the unit’s bodyframe in order

for the unit to function. See “Safety Interrupt Switch”

above. |

|

|

|

|

Note:

Tape securing lamp ends to lampholders must

be removed and discarded prior to use. |

|

|

|

|

|

Firm

pressure should be applied to the guard when

replacing it into an operating position so that the

interlocking fasteners join. |

|

|

|

COLLECTION

DRAWERS

|

|

|

|

Insect

collection drawers are packed inside some units.

These drawers should be periodically removed to

inspect and discard collected insect carcasses. |

|

|

|

|

|

|

|

|

TROUBLE

SHOOTING TIPS

|

|

|

|

|

|

| 1.

LAMP END DISCOLORATION |

|

3.

THE GRID ARCS CONSTANTLY |

|

|

|

|

|

a.

Discoloration of the lamp ends is normal in most cases

— and will not reduce lamp efficiency. |

|

|

|

|

a.

Inspect the electrical grid (please follow the |

|

|

procedure

described in Problem 2). If arc’ing

occurs at only one spot, shut off the electrical

current and clean the grid, making sure

the wires are not bent. |

|

|

|

|

| 2.

ONE OR BOTH LAMPS FAIL TO LIGHT |

|

|

|

|

|

|

| a.

Verify lamp pins are properly seated in the |

|

|

|

lampholders.

Using a non-electrical conducting

safety tool (insulated screwdriver, etc.), arc the grid

by holding the tool briefly between two grid wires.

This usually will start/light the lamps. If not, proceed

with the steps below. |

|

|

|

|

|

|

|

|

b.

Verify the line voltage. Line voltage above |

|

|

|

120

Volts may cause arc’ing, particularly in the

presence of high humidity/moisture. |

|

|

|

Note:

100-Ohm Resistors with installation

instructions are available from Insect-O-Cutor®.

Resistors may resolve spontaneous arc’ing

associated with environmental factors such as

humidity, etc. |

|

|

|

|

| b.

Check for loose wiring after disconnecting or |

|

|

|

shutting

off the electrical current to the unit. |

|

|

|

|

|

|

| c.

Replace inoperable lamp(s) with new IOC® insect |

|

|

|

attraction

lamps. First review Step (d) below. |

|

|

|

|

|

|

|

|

4.

THE LAMPS LIGHT — BUT THE GRID

DOES NOT ARC |

|

|

|

| d.

When replacing a black light insect attraction lamp |

|

|

that is not lit, follow the steps below to help prevent

burning out a new lamp unnecessarily: |

|

|

|

|

|

|

|

a.

Turn off the electrical current to the unit. |

|

|

|

|

|

|

b.

Inspect the grid carefully. Remove any foreign |

|

|

|

|

1.

Ensure that the electrical current to the unit has

been turned off. |

|

|

|

|

material

(gum, paper clips, steel wool, etc.)

adhering to the grid which can create a short

circuit between two grid wires. |

|

2.

Remove the unlit lamp. |

|

|

|

3.

Remove the other lamp in the unit that is lit. |

|

|

|

|

|

|

|

|

c.

Two or more grid wires may be touching each |

|

4.

Place the unlit lamp in the position from which

you have just removed the lit lamp. |

|

|

|

|

other

and causing a short circuit in the grid

(due to a special built-in safety shunt which

turns off the electrical current). In this instance

(unit already should have been turned off ),

separate and bend the grid wires apart with an

insulated tool . |

|

5.

Turn the unit on by closing the safety guard to

deactivate the interrupt switch and restore

electrical

current. |

|

|

|

|

|

|

If

the unlit lamp now lights, this indicates that the

ballasts in the first lamp position have possibly failed. |

|

|

|

|

|

|

d.

Inspect the high-voltage lead-in wires and |

|

|

|

If

the unlit lamp does not light, insert an ordinary white

fluorescent lamp (of the same wattage) in the position

originally occupied by the unlit lamp. If this lamp glows

red briefly and then goes out… or if this lamp does not

light at all, the ballasts which power this lamp position

are defective. |

|

|

|

insulators.

Make sure the wires are securely

attached to the grid. Check the insulators for

evidence of shorting. |

|

|

|

|

e.

Turn on the unit to ascertain whether the |

|

|

problem

has been corrected. |

|

|

|

|

|

| e.

If you have confirmed that one or more |

|

|

|

|

f.

If, after completing Steps (a) through (e) above, |

|

ballasts

are defective, it will be necessary to replace

them. Refer to the IOC® Replacement Parts List

(separate sheet) for the correct re-order information. |

|

|

|

|

the

grid still does not arc, it will be necessary to

replace the transformer. Refer to the IOC®

Replacement Parts List (separate sheet) for the

correct re-order information. |

|

|

|

|

|

|

|

|

|

|

DO

NOT INSERT FOREIGN OBJECTS INTO AN IOC® PRODUCT.

|

CAUTION:

Insect-O-Cutor® models are intended for use indoors only.

To avoid risk of fire or

electric shock, do not use where they may be exposed to direct

water or to direct sunlight

including roofed but open porches. Never install units near

explosion hazardous areas.

Refer to “Location Recommendations” above. |

|

|

|

|

|

|

5.

THE LAMPS DO NOT LIGHT — AND

THE GRID DOES NOT ARC.

|

|

6.

THE LAMPS OPERATE… THE GRID

FUNCTIONS — BUT INSECTS ARE

NOT ATTRACTED TO THE UNIT AS

WELL AS EXPECTED.

|

|

|

|

| a.

Inspect the unit to ensure that the safety guard is |

|

|

firmly

seated on the body/frame of the unit. |

|

|

|

|

|

|

|

|

a.

Changes in heating, lighting, cooling or air currents |

|

Note:

Partial removal or improper positioning of

the guard will activate the safety interrupt switch.

Electrical current will remain off until the guard has

been replaced. |

|

|

|

|

may

have made the present unit location obsolete.

Or, changes in lighting or door openings may have

caused re-routing of insect flight paths. |

|

|

|

|

|

|

|

|

In

any of these situations, refer to the “Location

Recommendations” on the top of this manual. |

| b.

Make sure the mainswitch/circuit breaker is “on” |

|

|

|

or

that the unit is, in fact, plugged in. Many times, a

plug will be accidentally removed from its socket or

a mainswitch/circuit breaker will be thrown into the

“off” position. |

|

|

|

|

|

|

|

|

b.

The lamps may be low in black light output. |

|

|

|

|

|

|

|

Insect-attracting

ultraviolet (UV) energy is produced

within a lamp by its phosphor, a dust-like coating.

Virtually all ultraviolet producing phosphors have

an effective life of only 7000 hours (or 9.5 months

of continuous use). |

|

|

|

|

| c.

Once you have verified that electrical current is |

|

|

|

flowing

to the unit and you note that the grid

still fails to arc, it will be necessary to check for any

loose wires. |

|

|

|

|

|

|

|

|

|

Insect

attraction lamps should be replaced on an

annual basis — with genuine Insect-O-Cutor® insect

attraction lamps. After 7000 hours of operation,

visible light (detectable to the human eye) will

continue to be emitted. However, the lamp’s UV

emissions are 50% below original emission levels. |

|

|

|

|

|

Shut

off the electrical current to the unit and

inspect wiring. Reattach the grid lead-in wires if

disconnected. Turn the unit back on to determine if

the loose wiring has been located. |

|

|

|

|

|

|

| d.

Check the line circuit for fuse/circuit breaker |

|

|

|

|

|

|

|

To

maintain insect-attracting effectiveness in light

traps, it is essential to replace insect attraction lamps

at least annually. |

|

failure. |

|

|

|

|

|

|

| e.

If, after completing Steps (a) through (d) above, |

|

|

|

the

lamps still do not light and the grid still does not

arc, it may be necessary to replace the transformer

and lamp ballast(s). Refer to the IOC® Replacement

Parts List (separate sheet) for the correct re-order

information. |

|

|

|

|

|

|

|

|

|

|

|

| Contact

us if any of the solutions outlined in these Trouble shooting

Tips fail to solve the problem(s). |

|

|

|

NOTE:

SHOULD YOU NOTICE INCREASED FLYING INSECT KILL IN PHASE III

UNITS

|

|

|

Phase

III units are positioned as the final line of flying insect

interception. Units in these areas act as monitors to

help gauge the efficiency of your IOC® system. Of all the

units operating in the system, Phase III equipment

should collect the least amount of insects. |

|

|

We

recommend that weekly catches be recorded, noting the amount

of insects collected as well as the type of

flying insects attracted and killed. Severe changes in these

recordings will warrant a closer inspection of your

facility’s integrated pest control programs. |

|

|

For

instance, a lower than normal insect kill denotes that an insect

electrocuting system is operating as expected. A

higher than normal insect kill warns that one or more problems

may exist in the insect elimination network. Examples: |

|

|

|

•

An exterior entry door (without benefit of an IOC® unit),

normally closed, now remains open for prolonged periods. |

|

•

One or more IOC® units have been unplugged or turned off

at the mainswitch for maintenance or cleaning,

and have not been returned to service. |

|

•

Transformers, ballasts, or lamps have failed in one or more

units, rendering them inoperable. |

|

•

An addition or expansion has been made to the facility that

requires additional IOC® units to complete the system. |

|

|

PREVENTATIVE

MAINTENANCE PROGRAM

|

|

To

obtain the highest possible level of flying insect elimination

and to ensure continued operational

efficiency, it is imperative that your Insect-O-Cutors®

be properly maintained . Please read this entire

manual before exercising any of the Preventative Maintenance

Procedures. Remember: disconnect the

electrical current to Insect-O-Cutor® units before beginning

repairs, maintenance or lamp replacement, etc. |

|

|

WEEKLY

|

|

•

Visually inspect units to determine that the black light lamps

are functioning.

• Using appropriate tools/devices, test unit electrical

grids for arc’ing activity.

• Replace any lamps that are burned out. If necessary,

replace any defective ballasts.

• Inspect, empty and clean the insect collection drawers

in all Insect-O-cutor® units at any time as safety may

dictate (i.e., when flying insect carcasses have

accumulated to an amount in excess of one inch

[or approximately 25 mm] ). |

|

|

MONTHLY

|

|

•

Inspect, empty and clean the insect collection drawers in all

units. Never permit insect carcasses to accumulate

to a depth of more than one inch (or approximately

25 mm). |

•

Clean the electrical grid with a non-metallic brush or broom.

Dust and dirt build-up insulates the grid wires,

allowing tiny insects to escape. Excessive

dust build-up may also create a fire hazard. |

•

Wipe the lamps with a dampened cloth. Any film or dust on the

attraction lamps will reduce black light emission

(flying insect attraction is directly proportional

to the amount of black light emission). |

•

Test the electrical grid to ensure that voltage is being attained

by arc’ing the grid with an appropriately

insulated tool . |

•

Wipe the surface of the unit with a dampened cloth whenever

dust and other particles detract from its appearance.

An Insect-O-Cutor® is an appliance that should

receive the same care and cleaning as other permanent fixtures. |

|

|

ANNUALLY

|

|

•

Replace all the lamps with genuine Insect-O-Cutor® Insect

Attraction Lamps. Each IOC® unit is equipped

with pretested black light lamps that will provide

the highest level of flying insect attraction. All lamps in

original

IOC® equipment are year-dated… exclusive

with the Insect-O-Cutor® product. |

|

Electric Fly

Killers, Fly Killers, Fly Traps, Flying Insect Killers, Insect

Glue Trap, Glue Traps, Insect O Cutor,

Insect-O-Cutor, Insect Electrocutors, and Insect Barriers

from your source for material handling equipment.

|

Back to Product

Page

|