Back to Product Page

|

MAGNA®

IMPACDOR®

|

|

|

|

|

|

The

Magna ImpacDor® is a flexible panel PVC door

designed for heavy-duty use. With a full width crystal clear

upper vision section for optimum safety and a gray opaque

lower impact section, the Magna ImpacDor® is ideal for

heavy-duty forklift, pallet jack, pushcart and pedestrian

use.

|

|

|

|

|

Engineered

for heavy-duty use The Magna is designed

for the most demanding commercial, industrial and food

processing applications where built-in durability is required.

Tough wear resistant .394” thick flexible PVC panels

absorb the initial impact of loads passing through the Magna

door. PVC panels are easy to clean and maintain and can be

inexpensively replaced when necessary. Also available in

Low Temperature formulation for freezers.

|

|

|

|

|

Durable,

maintenance-free, and easy to install

The Magna features galvanized steel hinges for corrosion

resistance. The Magna’s upper and lower mounting brackets

are low profile thus out of the way of impact collision damage.

Ninety percent of the Magna’s weight rests on the floor

so

no special jamb reinforcement is necessary. |

|

|

|

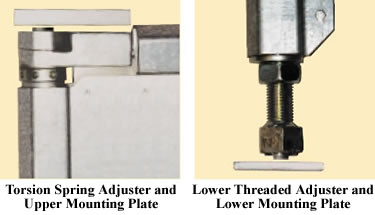

Adjustable

closing mechanism The adjustable torsion

spring closing mechanism allows the Magna to swing on an

even plane and can be adjusted to compensate for wind or

negative pressure conditions. Panels overlap in the

center 3” for better sealing. |

|

|

|

Custom

made to exact size The Magna ImpacDor®

may be custom made to suit your application for opening

sizes up to 8’ x 10’. Transoms (strip curtains)

are available for openings higher than 10’. |

|

|

|

|

|

|

|

|

|

|

|

Industrial

Plants |

|

Food

Processing Plants |

|

Pharmaceutical

and Medical Facilities |

|

Retail

Stores |

|

Features:

• Crystal clear PVC upper section

fused with gray

opaque PVC lower, .394” thick

• Opaque lower portion keeps door looking great

after repeated use

• Designed for heavy-duty industrial, commercial and

food processing traffic

• Adjustable torsion spring closing mechanism assures

180º swing capability on an even plane

• Lower threaded adjuster makes for quick and easy

installation and alignment

• Finished panels may be field modified by as much

as 4” in height and 5” in width.

Custom sizes available. |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

|

|

|

|

PRICING

|

|

Height |

Width |

|

5' |

6' |

7' |

8' |

| 7' |

|

|

|

|

| 8' |

|

|

|

|

| 9' |

|

|

|

|

| 10' |

|

|

|

|

|

| *

Call us for part numbers not shown, replacement part availability

and pricing. |

|

|

Magna

Specifications: 3/8" flexible PVC, clear

|

|

|

|

|

|

|

|

DOOR

FEATURES & OPTIONS

|

|

|

|

|

|

|

| PANEL |

|

|

|

|

3/8”

crystal clear PVC |

|

|

|

|

|

| FORMULATION |

|

|

|

[

] Standard (indoor/outdoor) |

|

[

] Low-Temp |

|

|

|

|

|

| HINGE |

|

|

|

Galvanized

full-length vertical frame of

13 or 11 gauge wall thickness (depending

on overall door size) |

|

|

|

|

|

| CLOSING

MECHANISM |

|

|

Adjustable

torsion spring. Swings on

even plane 180° . |

|

|

|

|

|

| FIELD

MODIFY |

|

|

|

Up

to 2” in height and 5” in width. |

|

|

|

|

|

| CUSTOM

SIZES |

|

|

|

Consult

us. |

|

|

|

|

|

|

|

Magna

ImpacDor® Installation Instructions

|

|

|

|

TOOLS

NEEDED

• Pen or Pencil to Mark Holes

• Drill

• Crescent Wrench

• Step Stool or Ladder

• Retaining Tool |

|

Receiving

and Handling |

|

|

|

Upon

receipt of your traffic door, uncrate and check unit for shipping

damage and/or missing parts. Any damage to the crate or packaging

material should be noted on the carrier bill of lading. Exterior

damage may

indicate concealed damage. |

|

|

|

Doorway

Preparation |

|

|

|

|

|

|

|

The

key to proper operation of your traffic door is that the lintel

is level and

the jambs plumb and square with the lintel. Building materials,

which make

up the lintel and jambs must be in good condition and solid

to accommodate

the weight and action of your traffic door. |

|

|

|

|

|

Traffic

Door Preparation |

|

|

|

|

|

Check

the dimensions of your doorway with those of your traffic door.

The

overall height of the traffic door panels (including hinge frame)

should be ¾”

less than the height of your doorway opening. Tighten the lower

threaded

adjustor (A) aligning the lower pivot pin (B) with the bottom

edge of your

PVC door panel (C). Open the spring arms (D) and slide down

over the

spacer plate (not shown in drawing). |

|

|

|

1.

Secure the upper mounting plate (F) centerline of lintel. |

|

|

If

necessary, use shims to insure it is level and square with

the door jambs. Secure with proper fasteners (not supplied)

depending on your lintel material or weld in place. |

|

|

|

|

2.

Position lower mounting plate (G) aligning the lower pivot |

|

|

hole

(H) with the pivot hole (I) in the upper mounting plate

(F). Secure with proper fasteners (not supplied) or weld

in place. |

|

|

|

|

3.

Raise traffic door panel to the vertical position guiding |

|

|

lower

pivot pin (B) into pivot hole (H) in lower mounting

plate (G). Be careful not to release the bearing enclosed. |

|

|

|

|

4.

Align upper pivot pin (J) with pivot hole (I) in upper |

|

|

mounting

plate (F). Screw out lower threaded adjustor

(A), which will raise the door panel into its proper position.

Be sure spring arms (D) slide over the upper adjustor (E)

located on the upper mounting plate (F). A space of 3/8”

should be left between the horizontal hinge arm and the

lintel of the opening. |

|

|

|

|

5.

Tighten locking nut (K) to secure door panel in place. |

|

|

|

|

|

6.

Use upper adjustor (E) to position the door panel in |

|

|

|

|

the

center of the lintel. After alignment is achieved tighten

locking nut. |

|

|

|

|

7.

Repeat same procedure for second traffic door panel |

|

|

(bi-parting

models only). |

|

|

|

|

Adjusting

the Tension

|

|

|

|

|

NOTE |

|

The

torsion spring mechanisms are adjusted at the factory

for normal operation of the traffic doors. Releasing the

tension completely is not advised and care should be taken

not to over-tighten as damage to the spring may occur. |

|

|

|

|

|

|

|

|

|

To

Increase Tension: |

|

|

|

|

1.

Open door panel to 90 degrees. Insert a retaining tool |

|

|

(N)

(not supplied) in the second free hole of the adjusting

ring (L) starting from the one into which the pin is already

inserted. |

|

|

|

|

2.

Allow the door panel to close slightly until the retaining |

|

|

tool

(N) inserted into the adjusting ring (L) rests against

the inside of the doorway. |

|

|

|

|

3.

Remove the pin and slowly recluse the door panel until |

|

|

the

inside hole of the mechanism matches up with the new

hole in the adjusting ring. |

|

|

|

|

4.

Insert the pin (M) in the new hole. |

|

|

|

|

To

Decrease Tension: |

|

|

|

|

The

procedure is the same as increasing the tension with

the following two differences: |

|

|

|

|

1.

The retaining tool must be inserted only one hole |

|

|

|

|

|

away

from the pin. |

|

|

|

|

|

2.

When the pin has been removed, the door panel must be |

|

|

opened

instead of closed to insert the pin in its new

position. |

|

|

|

|

NOTE |

|

Supra

Model door panels may be field modified. Ultra

Model door panels may be field modified up to 4” in width

and 2” in height. |

|

|

|

|

Magna Impacdor,

Door, Doors, Impact Doors, Impact Traffic Door, Impacdor,

Insect Barrier, Flap-R-Door, Hatchery Door, Rubbair

Doors, and Traffic Doors from your source for material handling

equipment.

|

Back to Product Page

|