Back to Product Page

TUFLEX

EYE AND EYE ROUNDSLINGS

|

|

|

|

|

|

|

| A

More Rugged and Durable Tuflex |

|

|

|

|

|

|

|

| The

Eye and Eye Advantage |

|

|

|

|

|

|

|

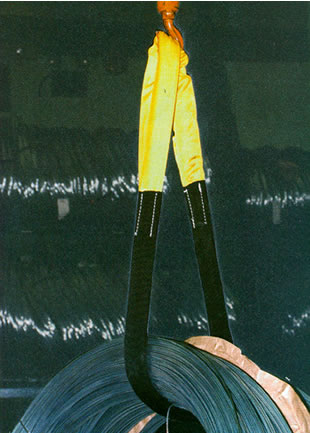

An

additional jacket of texturized, abrasion resistant

nylon covers the body of the standard Tuflex,

forming two color coded lifting eyes. |

|

|

|

|

|

|

|

| Maintains

all the basic Tuflex features plus... |

|

|

|

|

|

|

|

Saves money by extending sling life where

Saves money by extending sling life where

abrasion to sling body is a problem. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

*Constact

Us For Special Lengths*

|

|

|

|

Part

No. |

Color

of

Eyes |

Rated Capacity (lbs.)‡ |

Min.

Length

(ft.)+ |

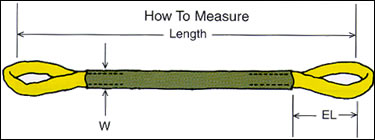

Approximate Measurements |

Ext'd. prices @ lgths shown (ft.) |

|

Vertical |

Choker |

Basket |

Wgt.

(lbs./ft.) |

Body

Width

at Load

(W)

(in.) |

Std Eye

Length

(EL)

(in.) |

Min.

Hardware

Dia.

(in.)** |

3' |

4' |

6' |

8' |

Adder/

Ft. |

|

EE30 |

Purple |

|

2,600 |

2,100 |

5,200 |

4 |

0.25 |

2 1/4 |

10 |

1/2 |

*NA |

|

|

|

$6.44

|

|

EE60 |

Green |

|

5,300 |

4,200 |

10,600 |

4 |

0.36 |

2 1/2 |

10 |

5/8 |

*NA |

|

|

|

$7.96

|

|

EE90 |

Yellow |

|

8,400 |

6,700 |

16,800 |

4 |

0.5 |

2 1/2 |

12 |

3/4 |

*NA |

|

|

|

$9.74

|

|

EE120 |

Tan |

|

10,600 |

8,500 |

21,200 |

5 |

0.6 |

3 1/2 |

12 |

7/8 |

*NA |

*NA |

|

|

$11.16

|

|

EE150 |

Red |

|

13,200 |

10,600 |

26,400 |

5 |

0.84 |

3 1/2 |

14 |

1 |

*NA |

*NA |

|

|

$14.61

|

|

EE180 |

White |

|

16,800 |

13,400 |

33,600 |

7 |

0.96 |

3 1/2 |

16 |

1 1/8 |

*NA |

*NA |

*NA |

|

$17.80

|

|

EE240 |

Blue |

|

21,200 |

17,000 |

42,400 |

7 |

1.5 |

4 1/4 |

16 |

1 1/4 |

*NA |

*NA |

*NA |

|

$20.08

|

|

EE360 |

Grey |

|

31,000 |

24,800 |

62,000 |

7 |

1.8 |

6 |

20 |

1 1/2 |

*NA |

*NA |

*NA |

*NA |

*NA |

|

EE600 |

Brown |

|

53,000 |

42,400 |

106,000 |

8 |

2.7 |

7 |

24 |

1 7/8 |

*NA |

*NA |

*NA |

*NA |

*NA |

|

EE800 |

Olive |

|

66,000 |

52,800 |

132,000 |

10 |

3.3 |

8 |

30 |

2 1/8 |

*NA |

*NA |

*NA |

*NA |

*NA |

|

EE1000 |

Black |

|

90,000 |

72,000 |

180,000 |

12 |

4.2 |

9 |

36 |

2 1/2 |

*NA |

*NA |

*NA |

*NA |

*NA |

|

|

|

|

|

*NA

- Quoted upon request. |

| ‡ |

|

|

Do

not exceed rated capacities. Sling capacity decreases as the

angle from horizontal decreases.

Slings should not be used at angles of less than 30°. Follow

instructions below. |

|

|

|

|

|

|

|

**This

is the smallest recommended connection hardware diameter to

be used for a vertical hitch. |

|

|

|

|

|

+

Shorter lengths available using reduced eye lengths. |

|

|

|

|

|

|

|

|

|

|

|

|

THE

TUFLEX DIFFERENCE

|

|

|

|

|

|

All

Lift-All slings meet or exceed OSHA and ASME B30.9 standards

and regulations.

|

|

|

|

|

| What

is a Tuflex Roundsling? |

•

Conforms to shape of load to grip securely

• Load bearing yarns protected from UV degradation

• Red striped white core yarns provide added visual

warning of sling damage

• Color coding provides positive sling capacity

information |

|

|

|

It

is an synthetic sling made from a skein (continuous

loop or hank) of polyester yarn covered by a double

wall tubular jacket. The roundsling body can also be

compared to sling webbing with the tubular jacket face

yarns woven without binder yarns; this allows the core

yarns to move independently within the jacket. |

|

|

|

Saves

Money

• Double wall cover for greater sling life

• Soft cover won’t scratch load surface

• Conforms to shape of load for reduced load damage

• Seamless - no sewn edges to rupture prematurely,

requiring removal from service

• EN360 and larger Tuflex feature Tufhide wear resistant

nylon jacket for extra sling life

• Tuff-Tag provides required OSHA information for the

life of the sling, not just the life of the tag |

|

|

|

| Tufhide

Jacket |

|

|

|

Made

from bulked nylon fibers, the double wall Tuf-

hide jacket offers better abrasion resistance for our

larger capacity Tuflex (EN360 and larger). In addition,

Tufhide reduces the heat buildup that can damage other

high capacity roundslings when used in a choker hitch. |

|

|

|

Tuflex

Roundslings

Features, Advantages and Benefits |

|

|

|

Saves

Time

• Color coded capacities for quick identification

• Light weight and pliable for easy rigging and storage

• Independent core yarns choke tightly, but release

easily after use

• Easy to carry - high strength to weight ratio for easy

transportation |

|

|

|

| Promotes

Safety |

|

•

Light weight reduces fatigue and strain on riggers

• Synthetic materials won’t cut hands

• Consistent matched lengths for better multiple sling

load

control

• No loss of strength from abrasion to cover

• Tuff-Tag provides serial numbered identification for

traceability

• Low stretch (about 3% at rated capacity) - reduces

sling and load abrasion - good for low headroom

lifts |

|

|

|

|

|

|

|

|

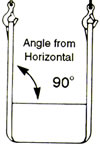

| Effect

of Angle of Lift on a Sling's Rated Capacity |

|

|

|

|

|

|

|

|

DEFINITION |

|

|

|

|

|

|

|

|

serves

to alert users to potentially hazardous situations which often

occur in the use of these products.

Failure to read, understand and follow the accompanying instructions

on how to avoid these situations

could result in death or serious injury. |

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is not taken

into consideration when selecting the sling to

be used. The tension on each leg of the sling is increased as

the angle of lift, from horizontal, decreases. It is most

desirable for a sling to have a larger angle of lift, approaching

90°. Lifts with angles of less than 30° from horizontal

are not recommended. If you can measure the angle of lift or

the length and height of the sling as rigged, you can

determine the properly rated sling for your lift. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

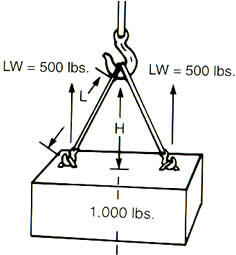

What

would be the rating of each sling

rigged at this angle? |

|

|

|

|

|

|

|

What

capacity sling do I need? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Determine the weight that the sling

will be lifting [LW]. |

|

|

|

|

|

|

|

|

| 1.

Calculate the Reduction Factor [RF]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to the

corresponding number of the

Reduction Factor column. |

|

|

|

|

|

2.

Calculate the Tension Factor [TF]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.

Using the angle from horizontal,

read across the angle chart to the

corresponding number of Tension

Factor column. |

|

|

|

|

|

|

|

|

|

|

|

-OR-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

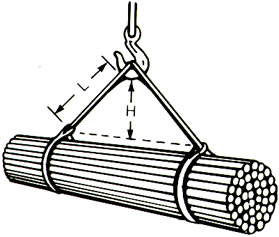

b.

Divide sling height* [H] by sling

length* [L]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-OR-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b.

Divide sling height* [H] by sling

length* [L]. |

|

|

|

|

|

Choker

Hitch

|

|

Vertical

Hitch

|

|

2.

Reduction Factor [RF] x the sling's

rated capacity for the type hitch that

will be used = Sling's Reduced Rating. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

Lifting Weight [LW] x the Tension

Factor [TF] = Minimum Sling Rating

for the type of hitch that will be used. |

|

|

|

Vertical

Basket

Hitch

|

|

|

|

*Measured

from a common horizontal plane to

the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reduced

Capacity

|

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart

|

|

Increasing

Tension

|

|

|

|

|

Reduction

Factor |

Angle

From

Horizontal |

Tension

Factor

(TF)

|

|

1.000 |

90º |

1.000 |

|

0.996 |

85º |

1.004 |

|

0.985 |

80º |

1.015 |

|

0.966 |

75º |

1.035 |

|

0.940 |

70º |

1.064 |

|

0.906 |

65º |

1.104 |

|

0.866 |

60º |

1.155 |

|

0.819 |

55º |

1.221 |

|

0.766 |

50º |

1.305 |

|

0.707 |

45º |

1.414 |

|

0.643 |

40º |

1.555 |

|

0.574 |

35º |

1.742 |

|

0.500 |

30º |

2.000 |

|

|

|

|

Example:

Vertical Choker rating of each sling = 6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667

Reduced sling rating in this configuration = .667

(RF) x 6,000 lbs. = 4,000 lbs. of lifting capacity

per sling

|

|

|

|

|

Example:

Load Weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1,000

lbs. per sling

|

|

Sling

capacity decreases as the angle

from hjorizontal decrease. Sling angles

of less than 30° are not recommended. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Polyester Roundslings,

Single Part Endless, Lifting Slings, Lift-All, Polyester Sling,

Eye and Eye, Braided Roundslings,

Tuflex, and Large Capacity Slings from your source for material

handling equipment.

|

Back to Product Page

|