Back to Product Page

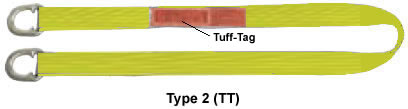

Type

2 (TT) Web-Trap Hardware Slings

|

|

|

|

|

|

|

|

|

|

Unilink

and Web-Trap hardware can help to

extend sling life by protecting the webbing from

abrasion on rough crane hooks. Hardware

can often be reused, lowering sling replacement

costs. |

|

|

|

|

|

Type

2 (TT) - Has a Web-Trap triangle on

each end. Normally used in a basket hitch, but

can also be used in a vertical hitch. They cannot

be used as a choker. |

|

|

|

|

|

|

|

Webmaster

1600 Nylon and Polyester* Slings

The Industrial Standard Heavy Duty Sling

|

|

|

|

|

|

|

This

grade of synthetic web sling is popular because most users

consider it's strength and service life a good buy. |

|

|

|

|

|

|

|

|

|

| Webmaster

Features, Advantages and Benefits |

|

|

|

|

|

|

|

| Promotes

Safety |

|

Saves

Money |

|

|

|

|

|

|

|

•

Red core yarn warning system aids in the inspection

process. |

|

•

Yellow treatment for abrasion resistance and extended

sling life. |

|

|

|

|

|

|

|

•

Tuff-Tag provides serial numbered identification for

traceability. |

|

•

Tuff-Tag provides required OSHA information for

the life of the sling, not just the life of the

tag. |

|

|

|

|

|

|

|

| •

Proven sling web construction. |

|

*

Note: Polyester web is identified by single blue

surface stripe. |

|

|

|

|

|

|

|

|

|

|

|

For

more information on web slings hardware

see below price table.

|

|

|

|

|

|

|

|

WEB

SELECTOR - QUICK COMPARISONS

|

|

|

Approx.

Thickness |

Single Ply Rated

Capacity Per In.

of Width |

Available

Material |

Identify by: |

Choose from: |

|

3/16" |

1600 Lbs. |

Polyester |

Blue center stripe |

Daily use under good

to moderate lifting

conditions. Polyester

stretches less for

better load control,

reduced abrasion.* |

|

3/16" |

1600 Lbs. |

Nylon |

No center stripe |

Daily use under good

to moderate lifting

conditions. Nylon

stretches more to

help avoid shock

loading.* |

|

|

|

HOW

TO ORDER

|

|

|

|

|

1.

Pick a Sling Type (TT)

2. Number of Plies (1 ply or 2 ply)

3. Web Class (8 = webmaster 1600) |

4.

Sling Width (2")

5. Web Material (D = Polyester or N = Nylon) |

|

| Example:

TT2802D |

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click a Price of the item you

wish to purchase.

|

|

|

|

|

|

|

*Contact

Us For Special Lengths* |

|

| **

Type 2 (TT) Web-Trap Hardware Slings |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

***

Part

No. |

Web

Width

(in.) |

Rated

Capacity* (lbs.) |

3' |

4' |

6' |

8' |

+/-

Per

Foot |

|

Vertical |

Choker |

V.

Basket |

One

Ply |

TT1-802D |

|

|

|

|

|

|

|

|

$3.26

|

|

TT1-803D |

|

|

|

|

|

|

|

|

$5.24

|

|

TT1-804D |

|

|

|

|

|

|

|

|

$6.69

|

|

TT1-805D |

5 |

8,000 |

6,400 |

16,000 |

|

|

|

|

|

|

TT1-806D |

6 |

9,600 |

7,700 |

19,200 |

|

|

|

|

$12.04

|

|

TT1-808D |

8 |

12,800 |

10,200 |

25,600 |

|

|

|

|

$19.23

|

|

TT1-810D |

10 |

16,000 |

12,800 |

32,000 |

|

|

|

|

$24.71

|

|

TT1-812D |

12 |

19,200 |

15,400 |

38,400 |

|

|

|

|

$30.04

|

|

TT1-816D |

16 |

25,500 |

20,400 |

51,000 |

|

|

|

|

|

Two

Ply |

TT2-802D |

|

|

|

|

|

|

|

|

$6.86

|

|

TT2-803D |

|

|

|

|

|

|

|

|

$11.09

|

|

TT2-804D |

|

|

|

|

|

|

|

|

$14.37

|

|

TT2-805D |

5 |

14,000 |

11,200 |

28,000 |

|

|

|

|

|

|

TT2-806D |

6 |

16,800 |

13,400 |

33,600 |

|

|

|

|

$24.94

|

|

TT2-808D |

8 |

22,400 |

17,900 |

44,800 |

|

|

|

|

$41.97

|

|

TT2-810D |

10 |

28,000 |

22,400 |

56,000 |

|

|

|

|

$55.58

|

|

TT2-812D |

12 |

33,600 |

26,800 |

67,200 |

|

|

|

|

$71.83

|

|

TT2-816D |

16 |

44,800 |

35,800 |

89,600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note:

2", 3", and 4" Hardware

Slings feature Unilink fittings. |

|

Three

and four ply hardware

slings are available upon request.

|

|

|

|

|

|

|

|

|

|

Cells

with red prices indicate shorter than recommended

lengths and may require reduced capacity ratings and/or

body lenghts. |

|

|

|

|

|

|

Web-Trap

Triangles and

Chokers are also available. |

|

|

|

|

|

|

**

Type 2 (TT) can not be used

in a choker hitch. |

|

|

|

|

|

|

|

***

Replace the "D" with an "N"

to order nylon. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

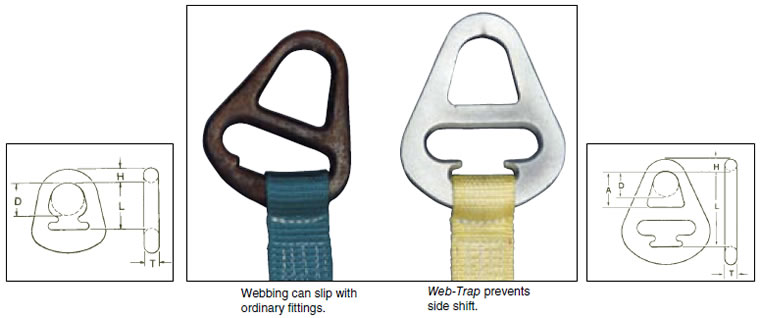

Web-Trap

Steel Sling Hardware - Triangles and Chokers

|

|

A

significant improvement in triangle and choker design - featuring

positive web capture. Webbing can slip to the

side of ordinary fittings, not with Web-Trap. These fittings

feature alloy steel for lighter sling weight and a zinc

dichromate plating to inhibit rust. |

|

|

|

|

Alloy Steel - For One

or Two Ply Slings

|

|

WEB TRAP TRIANGLES |

|

WEB TRAP CHOKERS |

Web

Width |

Part

No. |

Dimensions (in.) |

Part No. |

Dimensions (in.) |

|

L |

D |

T |

H |

Weight

(lbs.) |

L |

A |

D |

T |

H |

Weight

(lbs.) |

|

*2" |

ST-2 |

2 3/8 |

1 3/4 |

1/2 |

5/8 |

1 |

SC-2 |

5 |

2 3/8 |

1 3/4 |

1/2 |

5/8 |

1.9 |

|

*3" |

ST-3 |

3 7/16 |

2 |

1/2 |

3/4 |

1.9 |

SC-3 |

6 1/4 |

3 3/8 |

2 |

1/2 |

3/4 |

3.6 |

|

*4" |

ST-4 |

4 1/8 |

2 3/8 |

1/2 |

13/16 |

2.8 |

SC-4 |

7 |

4 |

2 3/8 |

1/2 |

13/16 |

5.1 |

|

6" |

ST-6 |

5 1/2 |

3 1/8 |

3/4 |

1 1/16 |

6.6 |

SC-6 |

9 1/2 |

5 1/2 |

3 1/8 |

3/4 |

1 1/16 |

12 |

|

Alloy Steel - For One

Ply Slings

|

|

WEB TRAP TRIANGLES |

|

WEB TRAP CHOKERS |

Web

Width |

Part

No. |

Dimensions (in.) |

Weight

(lbs.) |

Part

No. |

Dimensions (in.) |

Weight

(lbs.) |

|

L |

D |

T |

H |

L |

A |

D |

T |

H |

|

8" |

ST1-8 |

7 3/4 |

4 |

1/2 |

1 1/4 |

8 |

SC1-8 |

11 1/4 |

7 1/2 |

4 |

1/2 |

1 7/16 |

16 |

|

10" |

ST1-10 |

8 1/2 |

5 |

3/4 |

1 7/16 |

16 |

SC1-10 |

12 7/8 |

8 1/4 |

5 |

3/4 |

1 1/2 |

28 |

|

12" |

ST1-12 |

8 1/2 |

5 1/2 |

3/4 |

1 3/4 |

20 |

SC1-12 |

14 1/2 |

10 |

5 1/2 |

3/4 |

1 3/4 |

40 |

|

Alloy Steel - For Two

Ply Slings

|

|

WEB TRAP TRIANGLES |

|

WEB TRAP CHOKERS |

Web

Width |

Part

No. |

Dimensions (in.) |

Weight

(lbs.) |

Part

No. |

Dimensions (in.) |

Weight

(lbs.) |

|

L |

D |

T |

H |

L |

A |

D |

T |

H |

|

8" |

ST2-8 |

7 3/4 |

4 |

3/4 |

1 1/4 |

12 |

SC2-8 |

11 1/4 |

7 1/2 |

4 |

1/2 |

1 7/16 |

25 |

|

10" |

ST2-10 |

8 1/2 |

5 |

1 |

1 7/16 |

21 |

SC2-10 |

12 7/8 |

8 1/4 |

5 |

3/4 |

1 1/2 |

38 |

|

12" |

ST2-12 |

8 1/2 |

5 1/2 |

1 |

1 3/4 |

27 |

SC2-12 |

14 1/2 |

10 |

5 1/2 |

3/4 |

1 3/4 |

54 |

|

| *

Unlink is standard fitting - Triangle and chokers available

on special order only. |

|

WEB SLING

INFORMATION

|

|

|

|

|

| Sling

Length Tolerance for Web Slings |

Anti-Abrasion

Treatment |

|

| Sling

Type |

Tolerance

* |

| 1 Ply |

1.5"

+ 1.5% of sling length |

| 2 Ply |

2.0"

+ 2% of sling length |

| 3 &

4 Ply |

3.0"

+ 3% of sling length |

|

We

recommend that web slings be manufactured from

abrasion resistant latex treated webbing. Treatment is

standard on both nylon and polyester web slings.

Natural, untreated webbing is available upon request. |

|

|

|

Note:

Heavy duty treatments are available as a

supplemental process for greater protection. |

|

*

For web sling widths wider than 6", add 1/2" to these

values.

For tighter tolerance or matched set length requirements,

please consult with Customer Service. |

|

|

|

|

|

Elasticity

- The stretch characteristics of web slings

depends on the type of yarn and the web finish.

Approximate stretch at RATED SLING CAPACITY is: |

|

|

|

|

|

|

|

| Tuff-Tag

and Warning Sheet |

|

|

|

NYLON |

POLYESTER |

|

Treated |

10% |

Treated |

7% |

| Untreated |

6% |

Untreated |

3% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

Warning Sheet is

included with every web

sling order. The sheet lists

inspection information

and operating practices

applying to synthetic web

slings. |

|

|

OSHA

requires all web slings to show rated capacities

and type of material. The Lift-All Tuff-Tag is made from

an abrasion resistant polymer that will remain legible far

longer than any leather or vinyl tags. In fact, a Tuff-Tag

will consistently outlast the useful life of a sling. |

|

|

|

|

|

|

|

|

|

|

|

Tuflex

is an Alternative...

For three and four ply slings

wider then 6", Tuflex Rounslings should

be seriously considered.

Tuflex offers increased flexibility, ease of

use and lower cost.

|

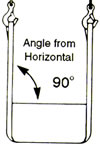

| Effect

of Angle of Lift on a Sling's Rated Capacity |

|

|

|

|

|

|

|

|

DEFINITION |

|

|

|

|

|

|

|

|

serves

to alert users to potentially hazardous situations which often

occur in the use of these products.

Failure to read, understand and follow the accompanying instructions

on how to avoid these situations

could result in death or serious injury. |

|

|

|

|

|

Using

slings at an angle can become deadly if that angle is not taken

into consideration when selecting the sling

to be used. The tension on each leg of the sling is increased

as the angle of lift, from horizontal, decreases. It is

most desirable for a sling to have a larger angle of lift, approaching

90°. Lifts with angles of less than 30° from

horizontal are not recommended. If you can measure the angle

of lift or the length and height of the sling as rigged,

you can determine the properly rated sling for your lift. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

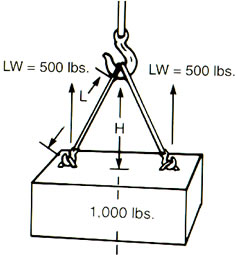

What

would be the rating of each sling

rigged at this angle? |

|

|

|

|

|

|

|

What

capacity sling do I need? |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.

Determine the weight that the sling

will be lifting [LW]. |

|

|

|

|

|

|

|

|

| 1.

Calculate the Reduction Factor [RF]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.

Using the angle from horizontal,

read across the Angle Chart to the

corresponding number of the

Reduction Factor column. |

|

|

|

|

|

2.

Calculate the Tension Factor [TF]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

a.

Using the angle from horizontal,

read across the angle chart to the

corresponding number of Tension

Factor column. |

|

|

|

|

|

|

|

|

|

|

-OR-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

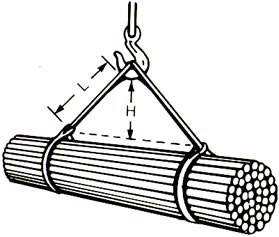

b.

Divide sling height* [H] by sling

length* [L]. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-OR-

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

b.

Divide sling height* [H] by sling

length* [L]. |

|

|

|

|

|

Choker

Hitch

|

|

Vertical

Hitch

|

|

2.

Reduction Factor [RF] x the sling's

rated capacity for the type hitch that

will be used = Sling's Reduced Rating. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3.

Lifting Weight [LW] x the Tension

Factor [TF] = Minimum Sling Rating

for the type of hitch that will be used. |

|

|

|

Vertical

Basket

Hitch

|

|

|

*Measured

from a common horizontal plane to

the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

*Measured

from a common horizontal

plane to the hoisting hook. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reduced

Capacity

|

|

|

|

|

|

|

|

|

|

|

Effect

of Angle Chart

|

|

Increasing

Tension

|

|

|

|

|

Reduction

Factor |

Angle

From

Horizontal |

Tension

Factor

(TF)

|

|

1.000 |

90° |

1.000 |

|

0.996 |

85° |

1.004 |

|

0.985 |

80° |

1.015 |

|

0.966 |

75° |

1.035 |

|

0.940 |

70° |

1.064 |

|

0.906 |

65° |

1.104 |

|

0.866 |

60° |

1.155 |

|

0.819 |

55° |

1.221 |

|

0.766 |

50° |

1.305 |

|

0.707 |

45° |

1.414 |

|

0.643 |

40° |

1.555 |

|

0.574 |

35° |

1.742 |

|

0.500 |

30° |

2.000 |

|

|

|

|

Example:

Vertical Choker rating of each sling = 6,000 lbs.

Measured Length (L) = 6 ft.

Measured Height (H) = 4 ft.

Reduction Factor (RF) = 4 (H) ÷ 6 (L) = .667

Reduced sling rating in this configuration = .667

(RF) x 6,000 lbs. = 4,000 lbs. of lifting capacity

per sling

|

|

|

Example:

Load Weight = 1,000 lbs.

Rigging - 2 slings in vertical hitch

Lifting Weight (LW) per sling = 500 lbs.

Measured Length (L) = 10 ft.

Measured Height (H) = 5 ft.

Tension Factor (TF) = 10 (L) ÷ 5 (H) = 2.0

Minimum Vertical Rated Capacity required

for this lift = 500 (LW) x 2.0 (TF) = 1,000

lbs. per sling

|

Sling

capacity decreases as the angle

from hjorizontal decrease. Sling angles

of less than 30° are not recommended. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Webmaster 1600

Slings, Lifting Slings, Sling, Nylon Slings, Lift-All, Nylon

and Polyester Slings, Industrial Standard

Heavy Duty Sling, Synthetic Web Slings, Serial Numbered Identification,

Triangles and Chokers, Eye and Eye Slings,

Flat Eye, Twisted Eye, and Endless Slings from your source

for material handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|