Back to Product Page

|

WIRE

ROPE HOISTS

ULTRA-LOW HEADROOM HOISTS (FE MODELS 4-5 TON)

|

|

|

|

|

|

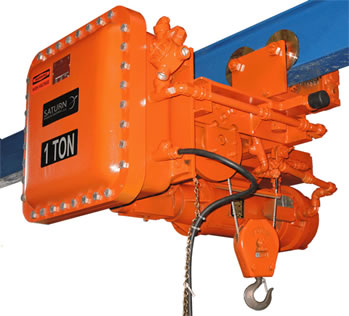

Our

Ultra-Low Headroom Series Hoists

provide Headroom that is unmatched in the

industry. When price is more of a concern

than Headroom or when curves need to

be negotiated, our Semi-Low Headroom

Series Hoists generally make a better

choice. Hoists from both series can be

purchased with Motorized or Plain Trolleys.

Our Semi-Low series is more versatile and

can also be bought Less Trolleys in a Lug

Mount configuration. |

|

|

|

5-Ton

Single-Reeved Ultra-Low Headroom Hoist

|

|

|

|

|

|

|

STANDARD

FEATURES

|

OPTIONAL

FEATURES

|

•

Capacities: 1 Ton to 5 Ton

• Lifts up to 50 Feet

• Low Headroom Design and Components

• Classification: ASME H4 Duty

• Suspensions: Motorized Trolley, Plain Trolley or Lug

Mount Type

• Worm Gearing: Both

Hoist & Trolley Drives

• Hoist Motor is rated 30-Minute Duty (Suitable for VFD

Operations above 20 HZ)

• Hoist Motor is TENV, Design “D” with Class

F

Insulation and Thermostat

• Hoist Brake is AC, Magnetic Disc Type (Rated at

150% Motor Torque)

• Trolley Motor is TEFC, Continuous Duty with Class B

Insulation

• Trolley Speeds: 35 or 60 FPM

• Primary Voltages: 230 or 460V-3PH-60HZ

• NEMA 1 Enclosure for Indoor Service

• Basic Single Speed Controls: Reversing Contactor(s),

Transformer, Terminal Strip

• Secondary Voltage: 115V

• Upper Paddle Limit Switch – Block Actuated

• Factory Balanced

• All Hoists Load Tested Prior to Shipment

• Safety Orange Paint

• ONE Year Warranty

• Heavy Duty Quality Construction

• Made in the USA |

•

Primary Voltages: 208V or 575V (3-Phase)

• Primary Voltages: 230V (1-Phase)

• Secondary Voltage: 24V

• NEMA 12: Enclosure

• NEMA 4: Weather-Proof Package

• Pendant: 2, 4, 6 or 8 Button Stations

• Radio Control Packages

• VFD Control Packages:

2-Speed Hoist

• VFD Control Packages:

2 Speed Trolley

• Inverter Duty Motors (Required for VFD Operations

under 20 Hz)

• Trolley Soft Start

• Mainline Contactor

• Branch Circuit Fuses: Hoist & Trolley

• Thermal Overload Relays and Motor Thermostats

• Gear Type Limit Switch

• Travel Limit Switches

• Overload Limit Switch

(Mounted Underneath Trolley)

• Trolley Motor Brake

• Drop Lugs: Trolley and Frame Type

• Hand Geared Trolley

• Explosion Proof Features

• Corrosion Resistant

Features

• High Temp/Hot Metal Features

• Curved Monorail Features – Hoist

& Tractor

Combinations

• FDA and Clean Room Features

• Air Powered: Single Speed Hoist Operation at 90 PSI

|

|

|

|

NOTE:

SEE BELOW FOR MORE DETAILS ON

THE OPTIONS AND PRICES. |

|

|

|

|

|

|

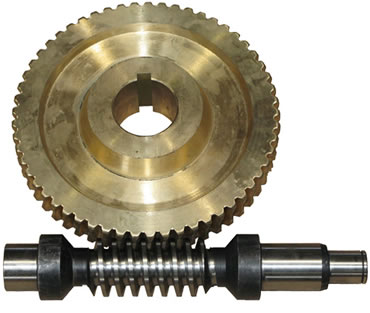

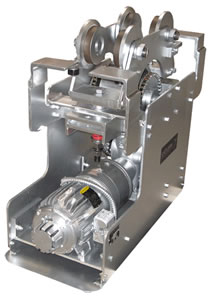

Standard Feature: Component Parts - Worm Gearing (H

& T) Features

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HOIST

WORM GEARING

|

|

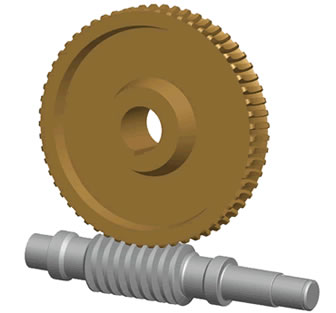

HOIST

WORM GEAR 3D MODEL

|

|

|

|

|

|

|

|

|

We

use Worm Gear Drives on all its Wire Rope Hoists, Drive Tractors

and Bridge Crane End Trucks as standard.

Worm Gear Drives are rugged and reliable and offer smooth and

quiet operation.

Due to their inherent

friction, Worm Gear Drives also act very similar to brakes

by retarding motion. For that reason,

brakes are generally NOT required on all our Worm Gear Trolleys,

Drive Tractors or End Trucks. Heavy capacity,

high momentum systems operating without VFD controls are sometimes

the exception. In these cases, the trolley or

crane may roll more than the acceptable limit without a brake.

For High-Ratio

Worm Gear Hoists, there are some major advantages over other

hoists.

|

|

|

|

|

|

|

|

|

•

High-Ratio Worm Gears safely control the lifting load without

the need for a Mechanical Load Brake.

• High-Ratio Worm Gears are inherently Self-Locking thus

these hoists are very capable of acting as 2nd

stopping brake and also holding up a load.

• Worm Gear Hoists have very Low Maintenance as fewer moving

parts lead to fewer repairs

• High-Ratio Worm Gear Hoists Conform to CMAA, ASME and

OSHA guidelines |

|

|

|

|

|

|

|

|

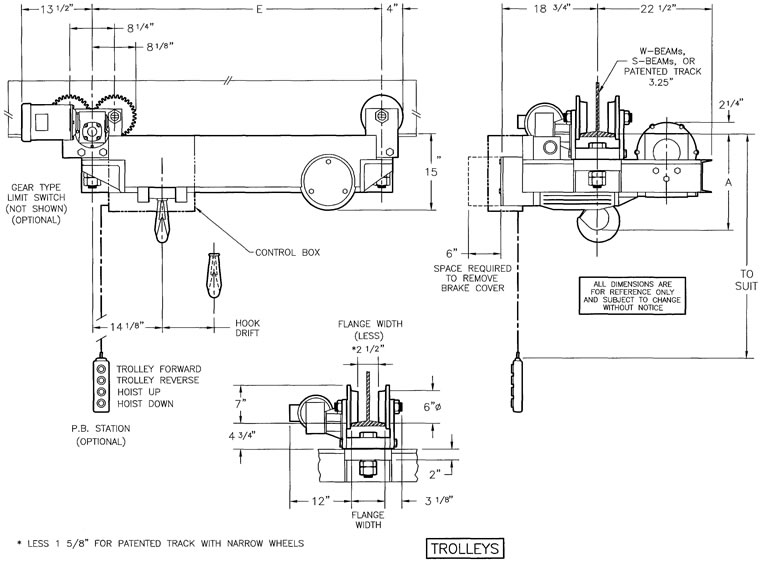

DRAWING

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Price of the item

you wish to purchase.

|

|

|

|

PRICES

FOR HOISTS

|

|

ULTRA-LOW HEADROOM (4PS) HOISTS 4 TO 5 TONS |

Prices |

Model

No. |

Capacity

(lbs.) |

Speed

(FPM) |

Lift

(ft) |

Reeving

Type |

Cable

(Dia) |

Hoist

Motor

(HP @ RPM) |

Head

Room

(A) |

Wheel

Base

(E) |

Hook

Drift |

Weight

(lbs) |

Motorized

Trolley

(MT) |

Plain

Trolley

(PT) |

|

FE8-1012

|

8,000

|

10

|

12

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

45

3/8"

|

3"

|

1200

|

|

|

|

FE8-1019

|

8,000

|

10

|

19

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

51

7/8"

|

4

1/2"

|

1275

|

|

|

|

FE8-1024

|

8,000

|

10

|

24

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

56

7/8"

|

5

3/4"

|

1350

|

|

|

|

FE8-1029

|

8,000

|

10

|

29

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

61

7/8"

|

7"

|

1425

|

|

|

|

FE8-1036

|

8,000

|

10

|

36

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

67

7/8"

|

8

3/4"

|

1500

|

|

|

|

FE8-1040

|

8,000

|

10

|

40

|

4PS

|

3/8

|

5

@ 1200

|

19"

|

73

3/8"

|

10"

|

1575

|

|

|

|

FE8-1512

|

8,000

|

15

|

12

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

45

3/8"

|

3"

|

1200

|

|

|

|

FE8-1519

|

8,000

|

15

|

19

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

51

7/8"

|

4

1/2"

|

1275

|

|

|

|

FE8-1524

|

8,000

|

15

|

24

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

56

7/8"

|

5

3/4"

|

1350

|

|

|

|

FE8-1529

|

8,000

|

15

|

29

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

61

7/8"

|

7"

|

1425

|

|

|

|

FE8-1536

|

8,000

|

15

|

36

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

67

7/8"

|

8

3/4"

|

1500

|

|

|

|

FE8-1540

|

8,000

|

15

|

40

|

4PS

|

3/8

|

7.5

@ 1800

|

19"

|

73

3/8"

|

10"

|

1575

|

|

|

|

FE10-1012

|

10,000

|

10

|

12

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

45

3/8"

|

3"

|

1200

|

|

|

|

FE10-1019

|

10,000

|

10

|

19

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

51

7/8"

|

4

1/2"

|

1275

|

|

|

|

FE10-1024

|

10,000

|

10

|

24

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

56

7/8"

|

5

3/4"

|

1350

|

|

|

|

FE10-1029

|

10,000

|

10

|

29

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

61

7/8"

|

7"

|

1425

|

|

|

|

FE10-1036

|

10,000

|

10

|

36

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

67

7/8"

|

8

3/4"

|

1500

|

|

|

|

FE10-1040

|

10,000

|

10

|

40

|

4PS

|

3/8

E

|

6

@ 1200

|

19"

|

73

3/8"

|

10"

|

1575

|

|

|

|

FE10-1512

|

10,000

|

15

|

12

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

45

3/8"

|

3"

|

1200

|

|

|

|

FE10-1519

|

10,000

|

15

|

19

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

51

7/8"

|

4

1/2"

|

1275

|

|

|

|

FE10-1524

|

10,000

|

15

|

24

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

56

7/8"

|

5

3/4"

|

1350

|

|

|

|

FE10-1529

|

10,000

|

15

|

29

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

61

7/8"

|

7"

|

1425

|

|

|

|

FE10-1536

|

10,000

|

15

|

36

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

67

7/8"

|

8

3/4"

|

1500

|

|

|

|

FE10-1540

|

10,000

|

15

|

40

|

4PS

|

3/8

E

|

10

@ 1800

|

19"

|

73

3/8"

|

10"

|

1575

|

|

|

|

**NOTES**

1. BASIC SINGLE SPEED (NEMA 1) CONTROLS (STANDARD); REV. CONTACTORS,

TRANSFORMER & TERMINAL STRIP

2. HOIST MOTOR THERMOSTAT (AS STANDARD)

3. PENDANT AND FURTHER MOTOR/CIRCUIT PROTECTION (ARE OPTIONAL

- SEE HOIST ACCESSORIES & OPTIONS)

4. FOR (NO) CONTROLS WITH WIRED J-BOX (NEMA 1) & BALANCED

HOIST - SAME PRICE

5. INDOOR OPERATION (AS STANDARD)

6. 230V OR 460V-3PH-60HZ (AS STANDARD)

7. TROLLEYS BUILT TO FIT S-BEAM, W-BEAM OR PATENTED TRACKS (AS

STANDARD)

8. FLANGE WIDTH UP TO 7" (AS STANDARD)

9. MOTORIZED TROLLEYS PROVIDED AT 35 OR 60 FPM (AS STANDARD)

10. GEAR TYPE LIMIT SWITCH (AS STANDARD) FOR LIFTS 35 FT &

OVER |

|

|

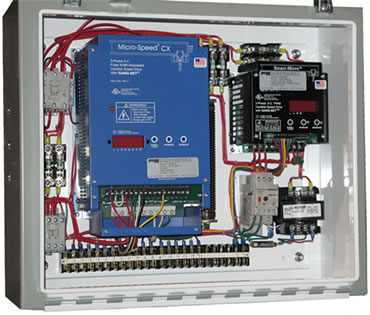

Optional

Feature: Component Parts -

Control Packages (Hoist, Trolley, Crane)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Custom

Control Panels

|

|

|

|

|

|

Panel

With VFD Hoist and Trolley Controls

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We

offer various Control Packages for all our Hoist and

Crane Equipment. Whether it is Standard or Custom, we

can build the control panel of your choice.

(VFD) Control

Packages are slowly becoming very popular

and are almost standard on all new equipment these days.

The benefits of (VFD) Controls by far outweigh its initial

costs. (VFD) Controls allow the operator to precisely and

safely control the load. Acceleration and deceleration rates

and 2-speed control limits are all set to best support the

given application. Any wear induced on mechanical parts

over time when using (VFD) Controls is much less.

|

|

|

|

|

|

Custom

Controls With Radio

|

|

|

|

|

|

|

|

|

| Please

see our photos for further reference on our control panels.

|

|

|

|

|

|

|

Optional

Feature: Component Parts - Overload Limit Switch

|

|

|

|

|

|

|

|

We

offer an Overload Limit Switch that is mounted

underneath one of our trolleys as an OPTION. This

Overload Limit Switch can be purchased with a

NEW hoist or for an EXISTING hoist and installed

in the field with minimal effort. This switch is adjusted

within 5% and there is no loss of headroom.

|

|

|

|

|

|

|

Overload

Limit Switch – Trolley Mounted

|

|

|

|

|

Optional

Feature: Wire Rope Hoists -

Special Environments - Explosion Proof

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Explosion

Proof Hoist

|

|

|

Trolleys

with Explosion Proof Motors

and Bronze Wheels

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Explosion

Proof Tractor with Bronze Wheels

|

|

Explosion

Proof Hoist with Spark Resistant

Features & Overload Limit Switch

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Machines

are designed in accordance with our interpretation of the specifications

of

the National Electric Code, Underwriters Laboratory and Factory

Mutual but are

NOT tested by them, nor do they carry their label as a whole.

However, most of the

Individual Electrical Components do carry an Underwriters Laboratory

(UL) Label.

Please NOTE; the

full responsibility for determining the existence and severity

of a

hazard in a specific area rests with the (Authority) responsible

for enforcing that code.

Additional

NOTES:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

•

Machines are available for Class I (Vapors): Groups C &

D and Class II

(Dusts): Group E, F & G (As Division 1 or 2)

• We use TENV motors as standard on all Division 2 applications

(With

Contained Hazard) as permitted by NEC code.

• Any requirements for Spark Resistant Features in severe

hazardous

environments lies with the (Authority)

• Spark Resistant Features generally include Stainless

Steel Wire Rope,

Bronze Trolley Wheels and Bronze Hook and/or

Complete Block. |

|

|

|

|

|

Explosion

Proof Pendant Station

|

|

|

|

|

|

|

|

|

|

Please

see our photos for further

product and component reference.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optional

Feature: Custom Hoists - Hoists for Corrosive Environments

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Stainless

Steel

Pendant Station

|

|

|

|

|

|

Hoist

& Tractor for Corrosive Environment with S.S. Enclosure

and Epoxy Finish

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This

equipment is for use in Corrosive Environments. Outdoor, Marine

and Dipping applications are some of the most

typical. Stainless Steel Components and Epoxy Paint are the

common features. |

|

|

|

|

|

|

| Please

see our photos for further reference. |

|

|

|

Optional

Feature: Custom hoists -

High Temp/Hot Metal Hoists

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EXTRA

HEAVY DUTY TRACTOR WITH

HIGH TEMP FEATURES INCLUDING

STEEL DRIVE WHEEL

|

|

|

|

|

|

|

HOT

METAL HOIST

|

|

|

|

|

|

|

Dependent

upon the severity of the application, we offer many different

features some of which are printed as guidelines by CMAA, ASME

and ASTM publications. |

|

|

|

|

|

Please

see our Equipment Photos as well as a

list of Hot Metal Hoist Features for further

reference. |

|

|

|

|

|

|

|

|

|

|

|

|

|

HOT

METAL HOIST FEATURES

|

|

|

|

|

|

|

|

|

•

Worm Gear Drive (As 2nd Braking Mechanism).

• Power Circuit Limit Switch.

• Gear Type (Upper & Lower) Limit Switch.

• Wire Rope with IWRC and 8:1 Safety Factor.

• Hoist Frame Mounted Safety Lugs.

• Rotating Light and /or Warning Bell for Trolley Motion.

• Heat/Splatter Shield under Hook Block.

• Heat Shields under Hoist and Trolley Drive Units.

• Class H Insulation for Hoist and Trolley Motors.

• NEMA 12 Enclosures.

• High Temp Internal Wiring. |

•

High Temp External Wiring with Metal Conduit.

• Magnetic Mainline Contactor.

• Motor Thermostats or Thermal Overload Relays.

• Branch Circuit Fuses.

• NEMA 12 Pendant with Metal Enclosure and Fire

Sleeve Cord Cover.

• High Temperature Oil in Reducers.

• High Temperature Grease in all Bearings.

• Rubber Bumpers.

• Oversized Hook – Hook Throat Opening and Radius

shall allow ladle bail to fit firmly in the bowl

of the hook. |

|

|

|

|

|

|

|

|

Optional

Feature: Custom Hoists -

Hoist and Tractor Combinations

|

|

|

|

|

|

|

|

|

|

For

superior trolley performance utilize a Hoist & Tractor

Combination.

The consistently

POSITIVE action of a drive tractor

will generally out-perform a standard motorized trolley

in many monorail applications.

By combining a

drive tractor with your hoist, you will

better negotiate curves, ride up inclines and will eliminate

nuisance slipping in many severe working environments.

Furthermore, the inherent beam tension of a drive tractor

can also serve to RESIST motion in certain applications

particularly when load swing or side-pull present motion

issues.

|

|

|

|

|

|

|

|

|

|

|

|

|

Rope

Guide Hoist with Tractor Drive

|

|

|

Please

see our photos for some examples.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Twin

Hook Hoist with Tractor Drive for

Outdoor Use on Curved Monorail

|

|

|

Semi-Low

headroom Hoist with Tractor Drive

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Order

Online, by Phone, or by E-Mail |

|

|

|

~

Add items to your online shopping cart ~

Click the Price of the item

you wish to purchase.

|

|

|

|

HOIST

ACCESSORIES AND CONTROL OPTIONS PRICES

|

|

|

DESCRIPTION

|

PRICES

|

|

FOR COMPLETE MOTOR & CIRCUIT PROTECTION

|

|

|

Hoist & Trolley B. C. Fuses, TOL'S or T'STATS &

Transformer Fuses (P & S)

|

|

|

SELECTIVE MOTOR & CIRCUIT PROTECTION ITEMS

|

|

|

Branch Circuit Fuses - Hoist (or) Trolley (Each Branch)

|

|

|

Thermal Overload Motor Protection (Each Motor)

|

|

|

Motor Thermostat (1/3 HP Motor - Only)

|

|

|

Transformer Fuses - (2) Primary & (1) Secondary

|

|

|

PENDANT - WIRED INTO HOIST CONTROLS WITH UP TO 16 FT

OF CHAIN DROP

|

|

|

2-Button Station

|

|

|

4-Button Station

|

|

|

6-Button Station

|

|

|

8-Button Station

|

|

|

CONTROL ACCESSORIES - ITEMIZED

|

|

|

Electronic (Trolley) Soft Start - Up to 4 AMPS (208/230/460V)

|

|

|

Mainline Contactor (15 AMP) - Includes 100VA Transformer

|

|

|

Mainline Contactor (30 AMP) - Includes 100VA Transformer

|

|

|

NEMA 12 Enclosure - (Dust Tight)

|

|

|

NEMA 4 Enclosure - (Water Tight)

|

|

|

Rotary Manual Disconnect (30 AMP)

|

|

|

Gear Type Limit Switch (2-Element)

|

|

|

Gear Type Limit Switch (4-Element)

|

|

|

VARIABLE FREQUENCY DRIVES (VFD) - HOIST

(INCLUDES P.E. DRIVE, FUSE PROTECTION & BRAKE CONTACTOR)

|

|

|

2HP (230/460V)

|

|

|

3HP (230/460V)

|

|

|

4-5HP (230/460V)

|

|

|

6-7HP (230/460V)

|

|

|

10HP (230/460V)

|

|

|

15HP (460V Only)

|

|

|

20HP (460V Only)

|

|

|

INVERTER DUTY - HOIST MOTOR (REQUIRED FOR LOW OPERATING

SPEEDS -

VFD SET UNDER 20 HZ)

|

|

|

2HP to 10HP (1800 RPM)

|

|

|

2HP to 6HP (1200 RPM)

|

|

|

7-1/2HP (1200)

|

|

|

VARIABLE FREQUENCY DRIVE (VFD) - TROLLEY (INCLUDES PE

DRIVE WITH FUSE PROTECTION)

|

|

|

1HP (230/460V)

|

|

|

2HP (230/460V)

|

|

|

3HP (230/460V)

|

|

|

INVERTER DUTY - TROLLEY MOTOR (REQUIRED FOR LOW OPERATING

SPEEDS -

VFD SET UNDER 15 HZ

|

|

|

1/3HP

|

|

|

1/2HP

|

|

|

3/4HP

|

|

|

1HP

|

|

|

1-1/2HP

|

|

|

TENZ MOTOR - TROLLEY (FOR OUTDOOR, WET OR VERY DIRTY

ENVIRONMENTS)

|

|

|

1/3HP

|

|

|

1/2HP

|

|

|

3/4HP

|

|

|

1HP

|

|

|

1-1/2HP

|

|

|

BRAKE - TROLLEY

|

|

|

Up to 1/2HP (STD Housing)

|

|

|

Up to 1HP (STD Housing)

|

|

|

Up to 1/2HP (NEMA 4 - Sealed Housing)

|

|

|

Up to 1HP (NEMA 4 - Sealed Housing)

|

|

|

|

| For

other options please contact us. |

|

|

|

Saturn Wire Rope

Hoists, Ultra-Low Headroom Hoists, Single Hook Monorail Hoists,

Electric Hoists, Powered Wire

Rope Hoists, Worm Gear Trolley, I Beam Hoists, Ultra-Low Headroom

Trolley Hoist, Worm Gear Hoists, and Electric

Wire Rope Hoists from your source for material handling equipment.

|

Back to Product Page

|

| HOME /

ORDER / SEARCH

/

QUOTE /

CONTACT US / ABOUT

US /

MY ACCOUNT/

SHOPPING CART |

|